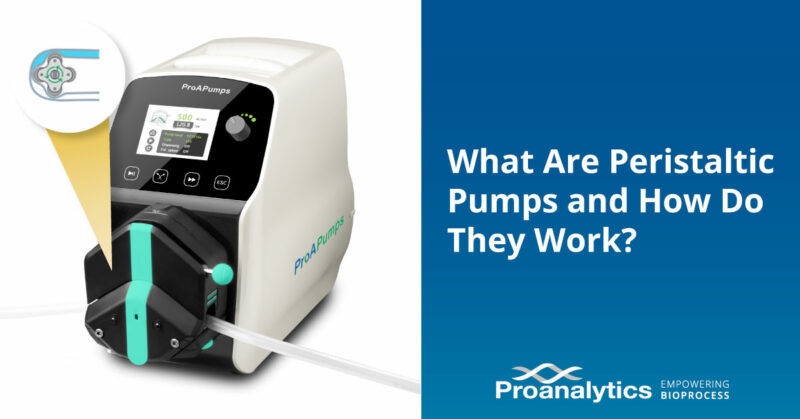

What Are Peristaltic Pumps? Peristaltic pumps — also called tubing pumps, roller pumps, or hose pumps — are important tools for medical, laboratory, and bioprocess/biopharma processes. They are a laboratory staple commonly used for processes such as fluid transfers, filtration/chromatography applications, volume dosing/metering, and volume control of all types of vessels. Peristaltic pumps are positive […]

Category Archives: Reports

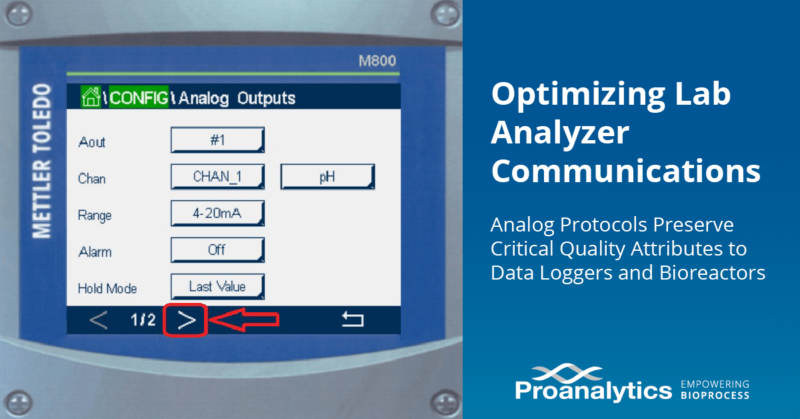

Introduction In the bioprocessing industry, bioreactor controllers are often used to tightly control many parameters within a bioreactor process run. The measurements that are controlled are called Critical Quality Attributes (CQAs) and include real-time pH, dissolved oxygen (DO), CO2, temperature, biomass and metabolites. Digital vs Analog Communication Protocols in Biotech Analyzers often have many different […]

Introduction The release of the FDA’s guidance on process analytical technology (PAT) for the biopharmaceutical industry has prompted the industry to embrace adaptive processes, employing advanced control strategies to ensure consistent product quality. Adoption of PAT has become very crucial as the bioprocess industry has grown rapidly over the past two decades. The development and […]

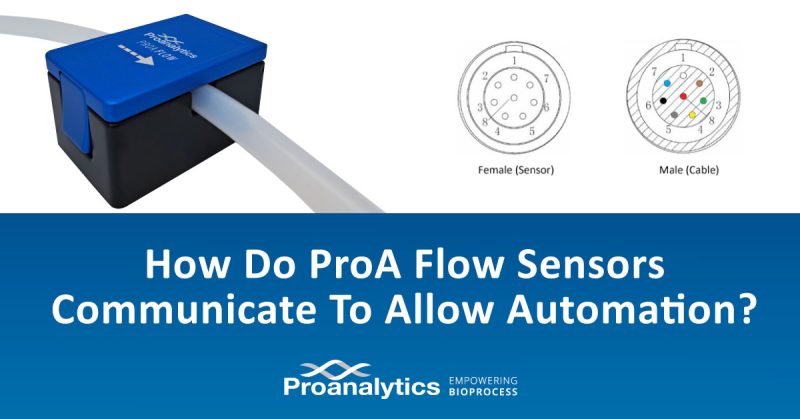

ProA Flow Sensors are ultrasonic clamp-on flow sensors that measure the flow rate to enable various applications. Integrating flow rate measurements into your existing process is key in automating these applications. For automation, ProA Flow Sensors use digital and analog communication protocols. Analog communication options: Digital communication options: Sensor Output and Cable Output Diagram ProA […]

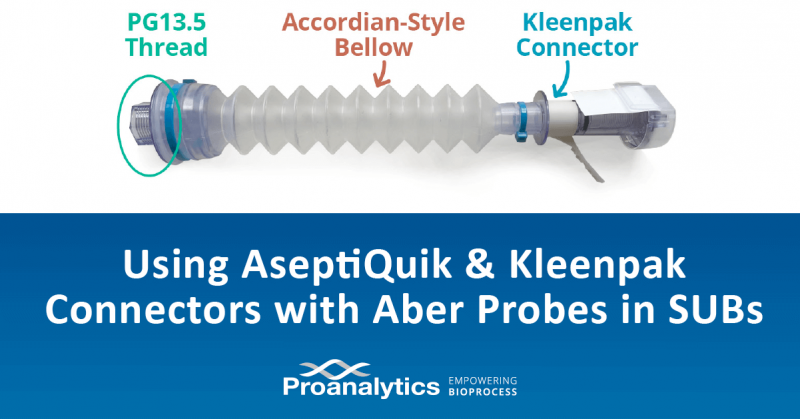

From traditional bioreactors to SUBs (Single-Use Bioreactors) Traditionally, bioreactors have been constructed from glass or stainless steel, and were designed to be reusable. However, in between batches, these vessels had to be carefully cleaned and sterilized prior to the next process being introduced. This cleaning process is labor-intensive and time-consuming. To reduce the costs and […]