Reports

How Do Peristaltic Pumps Work?

What Are Peristaltic Pumps?

Peristaltic pumps — also called tubing pumps, roller pumps, or hose pumps — are important tools for medical, laboratory, and bioprocess/biopharma processes. They are a laboratory staple commonly used for processes such as fluid transfers, filtration/chromatography applications, volume dosing/metering, and volume control of all types of vessels. Peristaltic pumps are positive displacement pumps that can pump a variety of fluid types, from aqueous to viscous fluids.

Pump Components: Peristaltic pumps are composed of a motor, pump head with rollers, and tubing. Since tubing is being used, there is little risk of contamination of the product because the fluid is contained inside the tubing. This eliminates the need for seals or valves like diaphragm pumps which are in direct contact with the fluid product. Peristaltic pump tubing must be elastomeric to allow for multiple compressions without damage.

How Do Peristaltic Pumps Work?

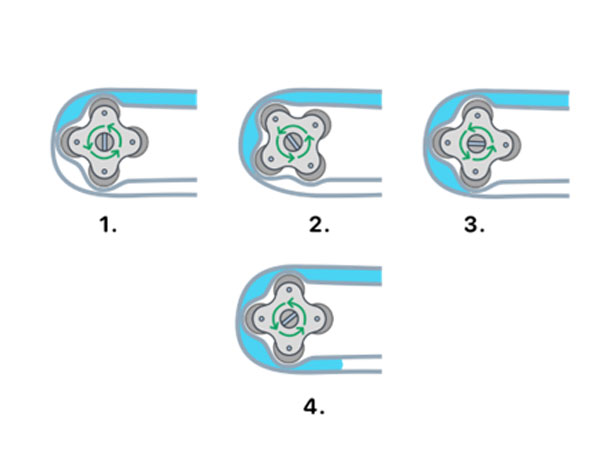

Peristaltic pumps work by compressing flexible tubing to move fluid through the tubing. This process creates a peristaltic wave that pushes the liquid forward with each compression of the tube. The rollers compress the flexible tube which opens back into its natural state, creating a vacuum which pulls more fluid into the tubing path.

Peristaltic Pumps and Occlusion

The actual compression of the tubing in the pump head is called occlusion. Occlusion can be represented as a percentage of two times the tubing wall thickness or an empirical amount of how much the walls have been squeezed. The roller heads allow for control over the flow rate, volume, and pressure, making them ideal for a variety of applications that need accuracy in fluid transfers. This compression and release of tubing is the same process used in many biological systems such as the contraction and release of the smooth muscles of the gastrointestinal tract or the locomotion of earthworms.

Peristaltic Pump Advantages

The main advantage of peristaltic pumps is that they can pump clean/sterile or highly reactive chemical solutions without exposing these fluids to exposed pump seals and valves in the fluid path. Only the chemical compatibility of the tubing needs to be tested.

Due to the rigorous demands of tubing in multiple processes, many companies specialize in extruding tubing with a wide range of chemical compatibility. Many tubing manufacturers have chemical compatibility charts specific to their tubing. If there is a chemical fluid that has not been tested with your choice of tubing materials, a simple immersion compatibility test can be performed. Small sections of tubing are cut and immersed in the chemical fluid for 24-48 hours and weighed. If the weight change is greater than 10% of the original weight, then that tubing is not compatible with your chemical solution.

ProA Pump Heads

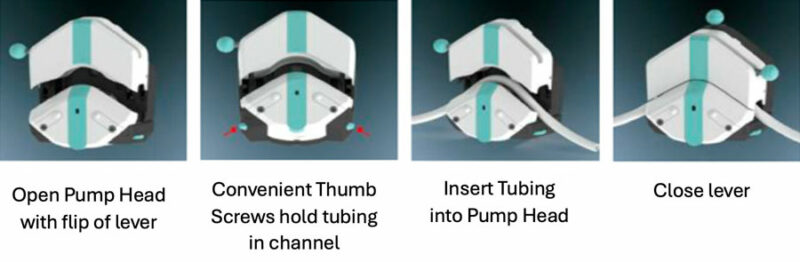

ProA Pumps have a wide selection of pump heads to fit a wide variety of tubing sizes.

The EP Tubing Loader feature (shown below) allows the operator to place the tubing inside the pump head quickly and with minimal effort, a design incorporated into all pump heads. Alignment of the tubing over the stainless-steel rollers is self-aligning.

The majority of ProA pump heads have 4 stainless steel rollers as standard. The choices for pump heads are single channel, dual channel (for pump Y or pump yokes), Fixed Pressure, and Adjustable Pressure. The Adjustable Pressure pump heads will lower the gap between the roller and the tubing. This allows for tighter contact and stronger compression of the tubing to increase accuracy.

Peristaltic Pump Tubing Considerations

However, users need to use special tubing in these pump heads because the amount of squeezing by a roller head can significantly decrease tubing life. As a result, many companies specialize in Pump-Resistant Tubing, such as Eldon James‘ EJ Prene pump tubing. Pump-resistant tubing is designed to withstand weeks of pumping without failure.

Designing single-use assemblies with pump-resistant tubing for specific pump heads will increase the life span of the tubing. This is critical for longer laboratory processes, such as perfusion in cell culture or bacterial chemostat cultures. Let the ProA engineers help design your next single-use assembly to maximize your success with ProA pumps.

Peristaltic Flow Rates, Roller Heads, and Pressure

Flow Rate

Users consider many factors when using a peristaltic pump to obtain an optimal flow rate.:

- Tubing ID – The greater the inner diameter of the tube, the higher the flow rate

- Tubing OD – The greater the outer diameter of the tube, the higher the flow rate

- Pump Motor – The higher the RPMs, the higher the flow rate

- Pulsation Effects – The roller or ‘pulse’ can affect the filling of the tube after compression which affects flow.

Number of Rollers/Roller Heads

The number of rollers in a pump head is also important. Increasing the number of rollers will not increase the flow rate, but it will lower the number of pulsations in the tubing line. The majority of ProA pump heads have 4X SS rollers as standard.

Pulsation is an issue with Peristaltic Pumps and could be an issue where the flow must remain constant (i.e., chromatography). More roller heads within the pump casing increases accuracy of the volume dispensed, decreases the amplitude of pulsations, but slightly lowers the flow rate. Pulsation becomes more of an issue when pumping at higher flow rates (high RPM), pumping through long stretches of tubing, or with high viscosity solutions. Adding more roller heads also decreases tubing life due to the number of occlusions. However, using a pump-resistant tubing will mitigate this issue on longer pumping processes.

Peristaltic pumps can operate up to 170 psi (12 bar) making them suitable for most Biopharmaceutical, Vaccine, Bioprocessing and Food & Beverage applications. ProA pumps are low maintenance and give years of reliable performance.

Be sure to check out our large selection of tubing, including silicone, TPE’s, pump-resistant tubing, and braided tubing for high pressure applications. Hopefully this article helped you answer the question, “how do peristaltic pumps work?” Please contact the author, David Koechlein, for more information about peristaltic pumps, pump tubing, and single-use assemblies.