Reports

A True Perfusion Bioreactor That Fits in the Palm of Your Hand

- Continuous True Perfusion™ culture at 2 mL scale provides an ideal platform to perform scale down and media optimization studies

- Comparable results to stirred tank bioreactors with significant savings in space and resources

- Capable of running multiple parallel experiments

With ERBI Breez™, get stirred tank performance at 2 mL scale!

Breez™ perfusion bioreactor is the only mL-scale platform that offers a fully automated, continuous True Perfusion™ culture. Its unique design allows it to accomplish everything normally done with a stirred-tank reactor and more. Its superior control provides the ability to easily run multiple experiments at once, with significant cost savings on every use.

Breez Perfusion Bioreactor Operational Functionality Summary

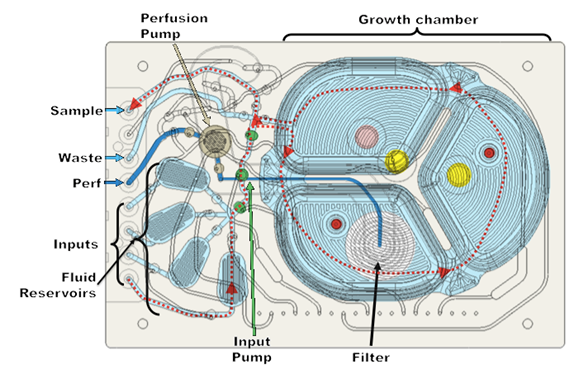

Breez Perfusion Cell Culture System consists of a base station hub and up to 4 controller PODS, each one being operated independently and controlled from ERBI software. The heart of the perfusion bioreactor system is a single use pre-sterilized mL scale microbioreactor cassette made of a multilayer silicone membrane which performs gas transfers, valving and mixing functions.

The Breez microbioreactor cassette includes an array of pumps and valves that keep the fluid in motion and provides a continuous input and output flow. The cassette includes integrated pH, pO2, pCO2 and temperature sensors and a 1.2 um ATF filter. The fluid enters the cassette from one of 4 inputs, and exits through outlets connected to the external transfer bottles which are already attached and jointly pre-sterilized with the cassette.

An integrated reservoir fills, which runs a 3 valve input pump.

Each cassette contains a single input pump which can be switched between 4 different input lines. By taking advantage of microfluidic structures, this sub-microliter pump is integrated into the disposable fluid path. This type of pump allows very consistent volumetric flow rates independent of the fluid being sourced. Since there is only one pump for the single use assembly, each cassette is delivered precalibrated providing maximum accuracy before its use.

The pump injects fluid into the growth chamber which consists of 3 main compartments where the cells continually circulate. The compartments are interconnected at the edges and 2 of the 3 are always full as the fluid is kept in motion, maintaining the required circulation. Periodically, the fluid in each section is partially expelled to generate flow into the other two sections, achieving the necessary mixing and gas transfer. The cell retention filter integrated into the base of the growth chamber is continuously being cleaned by the fluid circulation on the surface of its membrane. The filter surface area to volume ratio is representative of typically sized ATFs or TFFs used with stirred tank bioreactors.

For fluid removal, the growth chamber can be pressurized and fluid can be selectively removed through one of three ports, either through the perfusion filter to a perfusion collection bottle, through a waste port to a cell waste bottle, or through a sampling port to a sampling tube. The sample size accumulated during a typical 24 hour run allows it to perform the necessary nutrient and metabolite measurements at the right frequency.

For further and complete details and description of the Breez Perfusion Bioreactor System and its amazing features please read this case study published by Cell Culture Dish.