Reports

Using AseptiQuik & Kleenpak Connectors with Aber Probes in Single-Use Bioreactors

From traditional bioreactors to SUBs (Single-Use Bioreactors)

Traditionally, bioreactors have been constructed from glass or stainless steel, and were designed to be reusable. However, in between batches, these vessels had to be carefully cleaned and sterilized prior to the next process being introduced. This cleaning process is labor-intensive and time-consuming. To reduce the costs and turnaround time between batches, many biotech companies have adopted single-use bioreactors (SUBs) or single-use fermentors (SUFs) which are made from disposable plastics. With the use of these disposable vessels, a new one is used each time a process run is initiated. Suppliers typically deliver these vessels pre-sterilized via gamma irradiation and double-bagged, making them ready for use right away.

During the bioreactor process, it is crucial to monitor various parameters, including pH, temperature, dissolved oxygen (DO), metabolites, and biomass. These parameters are known as Critical Process Parameters (CPPs). In traditional, reusable bioreactors, reusable probes were inserted into the vessel to monitor these parameters, and then the entire tank assembly was sterilized – typically through autoclaving, Steam In Place (SIP), or Clean In Place (CIP). This sterilization process not only sterilized the tank but also the in-situ probes that monitor these CPPs.

Understanding probe autoclave bellows

When single-use vessels were first introduced to the biotech market, there was a significant concern about how to insert non-sterile reusable probes into a sterile vessel.

To address this issue, reusable probes were enclosed in a single-use plastic probe sheath. The disposable sheath fully enveloped the probe, thus sealing it off from the outside environment and/or potential contaminant risks. The entire probe and sheath assembly were then autoclaved, resulting in a sterile probe inside a sheath.

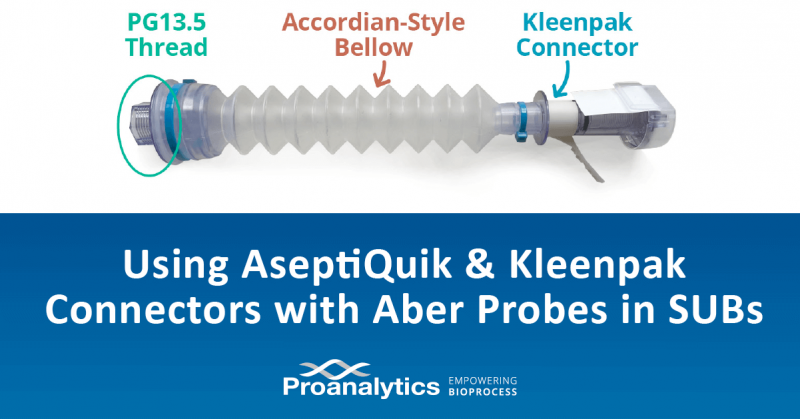

The sheath bellow assembly was made up of three major components:

- The threads where the probe screws in

- The tube-shaped, accordion-style bellow

- And the AseptiQuik or Kleenpak aseptic connector.

One side of the autoclave bellow assembly had PG13.5 female threads where the probe head screwed into. PG13.5 is a 13.5mm diameter thread often used on reusable biotech probes, such as Aber biomass probes or Mettler pH, DO or CO2 probes.

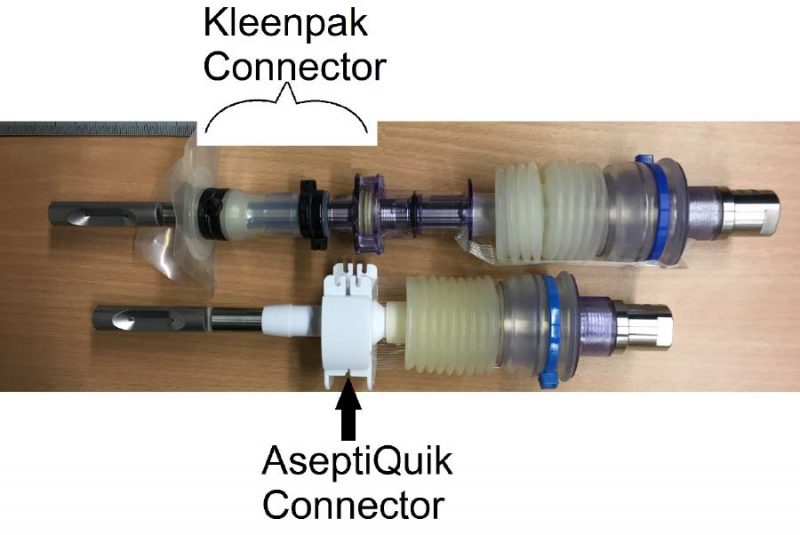

The opposite side of the bellow had the Kleenpak or AseptiQuik aseptic connector where the probe tip would be pushed through a sterile diaphragm to introduce the tip of the probe into the bioreactor vessel. The user simply selected the probe sheath bellow enclosure with either a Kleenpak or gender-less AseptiQuik connector on it to match the type of aseptic connector that was on the single-use vessel.

The entire assembly, consisting of the PG13.5 connector, accordion-style bellow enclosure, and AseptiQuik or Kleenpak, is commonly referred to as an “autoclave bellow assembly.”

How aseptic connectors work

The key to maintaining sterility during the connection process is the use of a pre-sterilized membrane that is placed inside the sterile Kleenpak or AseptiQuik connector. This membrane acts as a barrier to prevent any contaminants from entering the probe pathway during the connection process of inserting the probe into the vessel or bag.

To establish a connection between the probe side and reactor side, the two ends are mated and the Aseptic membrane separating both sides is removed. This opens up the sterile path, allowing the probe to be inserted into the reactor as the bellows collapse.

Autoclave bellow assemblies for DO and pH probes

5-fold accordion style

The industry standard probe length for SUBs and SUFs is 220mm, so a 5-fold accordion-style bellow was often used as it was long enough to envelop a 220mm long probe. This length was deemed adequate for insertion into the vessel, clearing the vessel wall without protruding too far into the tank and interfering with other bioreactor components, such as the agitator. This design was suitable for DO and pH probes since these technologies measure oxygen or pH right at the probe tip’s surface.

Choosing the right single-use connector for your Aber biomass probe

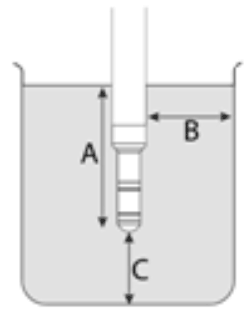

For capacitance-based biomass sensors, however, the dimensions of the measurement field extend three dimensionally around the tip of the probe approximately the size of a golf or tennis ball around from the probe tip. The clearance requirements for the small measurement geometry are shown as follows:

| Minimum Probe Clearance | Standard |

|---|---|

| A – Immersion depth (mm) | 60 |

| B – Side clearance (mm) | 40 |

| C – Base clearance (mm) | 40 |

The measurement signal is generated in this area and uses capacitance-based technology to determine the biomass within this volume. Any live cells that pass through this volume are detected as viable biomass.

Using an AseptiQuik connector with an Aber probe

When a user’s SUB has an AseptiQuik on it, a mating autoclavable genderless AseptiQuik bellow should be used. The AseptiQuik brand connector does not have deadspace within its design, and the probe is not backed out of the bioreactor due to any deadspace. For this reason, the traditional 220mm length capacitance biomass probe can be used, along with the usual 5-fold bellow that is typically used for pH, DO and CO2 probes. There are no special considerations that need to be taken into account when using a biomass probe on a SUB that uses an AseptiQuik connector.

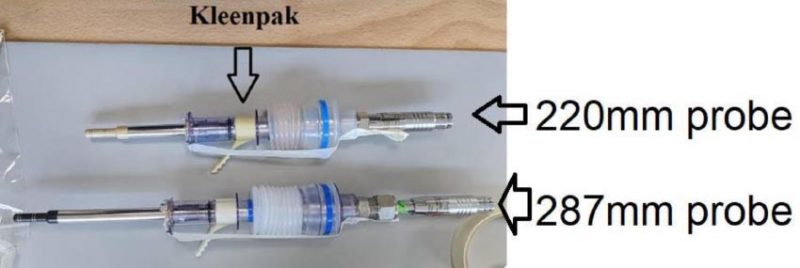

Using a Kleenpak connector with an Aber probe

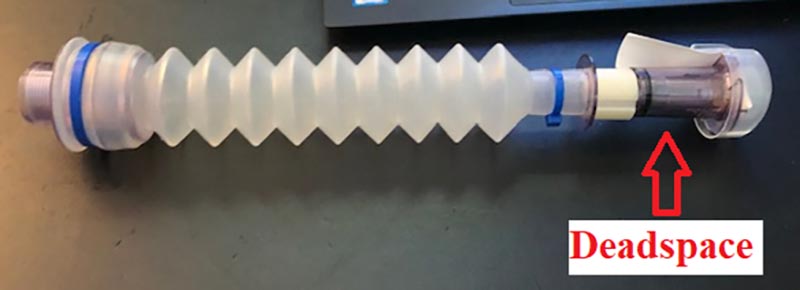

The Kleenpak brand connectors used in capacitance-based biomass sensors were found to have introduced some dead space between the tip of the probe and the bioreactor wall when compared to a bellow with an AseptiQuik brand connector. To obtain an accurate biomass measurement, the tip of the probe needs to protrude beyond the bioreactor wall by about 30mm so that the full measurement geometry is inside of the bioreactor wall, assuring the measurement field is not interfered with or reduced.

Because the measurement geometry for capacitance-based biomass measurement is a 3D geometry (as opposed to a surface measurement),the probe tip must protrude further into the vessel than a traditional DO or pH probe.

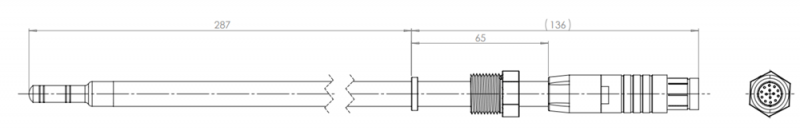

When using a Kleenpak autoclave bellow, a probe longer than the traditional 220mm length is required to clear the dead space created by the Kleenpak connector. The leading manufacturer of capacitance biomass sensors, Aber Instruments, designed a longer probe with an insertion length of 287mm to resolve this problem.

The longer insertion length overcame the design limitations and ensured that the probe tip was inserted further than the SUB wall by approximately half the diameter of a tennis ball, which helped achieve a strong biomass measurement and ensured that the measurement geometry was fully inside the bioreactor.

Autoclave bellow assemblies for capacitance-based sensors

9-fold accordion style

However, the longer probe did not fit within the standard 5-fold autoclave sheath assembly, so a longer 9-fold bellow-style probe sheath enclosure was designed to accommodate the longer probe during the autoclave process.

Increasing the probe length to 287mm from the standard 220mm insertion length was a crucial first step in addressing the dead space challenges caused by the Kleenpak connector. With the longer probe in place, the industry focused on designing an enveloping probe sheath to fully encapsulate this probe, which led to the creation of the 9-fold probe bellow. This bellow has the advantage of accommodating longer probes which ensures that the measurement geometry of the capacitance-based biomass probe is fully inserted beyond the SUB/SUF wall.

From Aber (source): “For users of the KleenPak sterile connectors, Aber recommends using a 320mm sensor with a custom PG13.5 fitting (PN: 6570-52). The increased sensor length and optimized PG nut positioning maximize sensor immersion and bioreactor penetration, while still fitting inside the bellows, and ensuring a secure connection”

Conclusion

In conclusion, single-use bioreactors (SUBs) have become increasingly popular in the biotech industry due to their cost-effectiveness, faster turn-around time and reduced labor requirements. However, the use of non-sterile reusable probes with sterile vessels presented a challenge, which has been addressed through the development of aseptic connectors such as Pall’s Kleenpak and CPC’s AseptiQuik (ASQ). These connectors, along with specially designed bellow-style enclosures, allow for the insertion of reusable probes into sterile vessels in a sterile and efficient manner. While the standard design works well for pH, DO and CO2 probes, capacitance-based biomass sensors require longer probes to ensure accurate measurements, leading to the development of longer bellow-style enclosures. Overall, the adoption of SUBs and sterile connectors has significantly reduced the time and cost associated with bioreactor cleaning and sterilization, allowing for more efficient and cost-effective biotech processes.