Reports

Continuous Perfusion Microbioreactor for Process Development and Cell Therapy Applications

Enabling Rapid Bioprocessing Innovation, or Erbi, is an engineer-founded company with a strong message, building the industry’s first automatic, integrated, milliliter-scale bioreactor. The Erbi Breez™, their flagship product, was launched in 2020 and includes the company’s foundational technology.

The 2-mL scale miniature bioreactor, capable of both continuous perfusion and fed batch processes, aims to expedite and simplify two broad applications: bioprocess process development and cell therapy. This true perfusion cell culture system includes four controller ‘PODs’ that simultaneously mimic stir tank abilities and more, with data collected by the base station and analyzed with an intuitive software. For an in-depth review of the Breez™’s technical capabilities, please read A True Perfusion Bioreactor That Fits in the Palm of Your Hand.

Continuous Perfusion Key Applications

With a recent increase in funding and management, Erbi is directing their efforts towards marketing, with the goal of educating the bioprocess arena on the advantages of true perfusion at a milliliter scale.

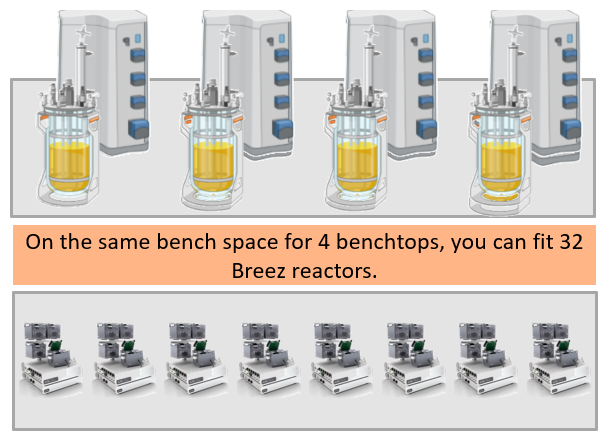

A key advantage of the Breez is its ability to mimic 3 to 10L bioreactor systems while only using one linear foot of bench space. Combined with the ability to run four parallel continuous perfusion cell cultures, researchers can cut operation time by ¼ and still test multiple parameters. Producing more data in less time creates massive savings in operational costs, using less media than traditional bioreactors.

Another key advantage is automation. All a researcher must do is drop the cassette in the POD and run the experiment, allowing tests to run over the weekend without the need for overview. With Covid-19 staffing restrictions in place, the need for process development and dealing with backlogs within labs, the Breez could function as a backup system. It takes up little space, and is available to help researchers overcome busy situations.

Cell therapy, an emerging application, is requiring scientists to learn more about cell behavior and optimal conditions to modify and grow patient cells. Researchers would benefit from the Breez’s high cell density capabilities, accumulating more data from less runs than stir tanks. Normal stir tank cell densities reside around 100 million cells/mL, while customer data has shown 250 million cells/mL within the small cassette of the Breez.

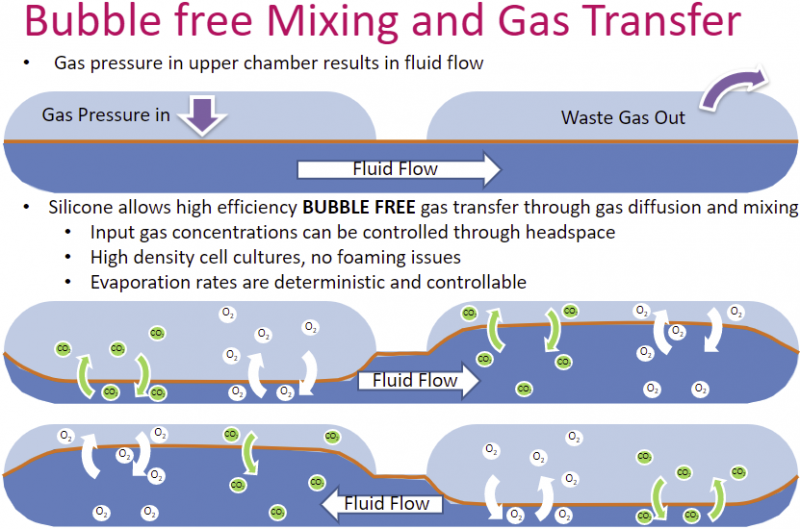

Increased cell density is made possible by the unique gas transfer and mixing operation within the cassette. An inflatable silicone membrane mixes the culture media and simultaneously diffuses necessary gases, removing bubbles and foam. The reduction in foam and removal of an impeller decreases shear stress on cells significantly, allowing for a gentle process.

Intensification

Recently, there has been a substantial shift to intensified processes which includes moving to online sensing, tightly integrated systems, and digitization. The Breez allows researchers to intensify their process with less effort and less media, removing cumbersome media handling and long inoculation preparations. Ultra-high cell densities are acquired with no need for complex accessories or interconnections. All required materials – bottles, pumps, filters, and online sensors – are integrated into the disposable cassette. There is no time spent on reactor set up, sterilization, tear down, and clean up, since the consumables are simply disposed of, and the Breez is ready to start the next run.

Also, risk of contamination is drastically decreased by the significant reduction in human touch points. Erbi explains, “Our continuous perfusion system is simple enough that one technician with little bioreactor experience can run 12 simultaneous experiments.” In the same space 4 benchtop stir tanks would normally fill, 32 microbioreactor systems can be installed with no other accessories required.

Essentially, researchers could increase data output by 8x, while requiring fewer technicians in the same space. Erbi’s goal is clear: to help scientists do more than they can with a standard bioreactor and get reliable results faster and more economically.

Future Work

Erbi is a small company that has the potential to set future precedent for an entire industry with a single flagship product. However, they are not stopping there, as the company has plans in 2021 to begin product expansions. They understand the 2-mL scale may be too small for some applications, so Erbi is contemplating a larger reactor, with more working volume, yet keeping the same key advantages of full integration and autonomy. They plan to investigate ways to add more inputs and outputs for analysis, integration, and data connectivity tools.