CO2 Incubator for Cell Culture

The CelCulture®, Esco’s CO2 incubator for cell culture, is a state of the art machine specially developed for the demanding cell culture bioprocess laboratory or GMP site. Systems feature robust contamination control, direct heat and air jackets, anti-grip SS shelving, cleanable surfaces, single beam IR sensor with autozero, and more.

There is a large selection of models for different capacities and materials of construction.

FEATURES:

- ULPA Filter with 99.999% efficiency which exceeds performance of HEPA Filters

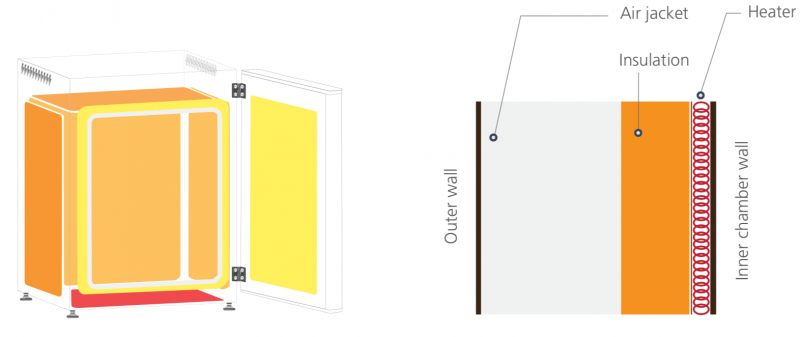

- Direct Heating / Air Jacket for rapid temperature recovery and fast and uniform heating

- Internal Blower for further temperature uniformity

- Heated Front Door eliminates condensation

- Sample Port for O2 and CO2 measurement

- Inner Glass Door for process observation

- Smart Sense Microcontroller Interface for monitoring, datalogging and control

- IR CO2 / Electrochemical O2 Sensors and UV Lamp to ensure water and air sterility

- Available in 3 sizes: 50L, 170 L and 250 L

VIVOCELL™ PRECISE PARAMETER CONTROL

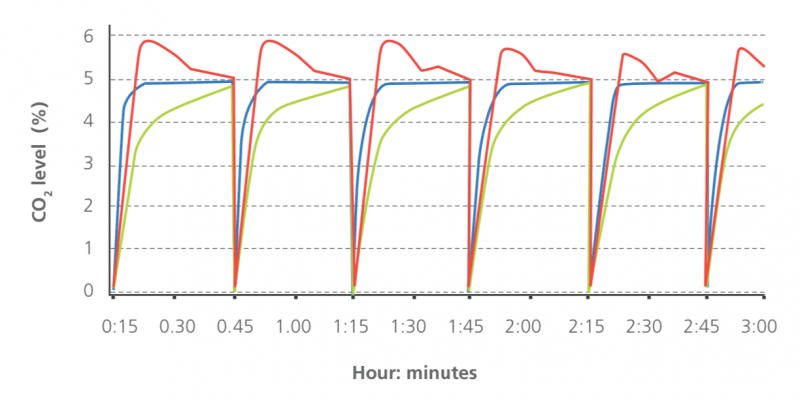

Precisely-tuned sensor and software result in fast recovery of CO2 without overshoot. This ensures uniform CO2 levels even with frequent incubator door opening. Recovery of both temperature and humidity is twice as fast as a conventional CO2 incubator for cell culture.

- Direct heating enables rapid temperature recovery while air jacket provides isolation against ambient temperature fluctuations.

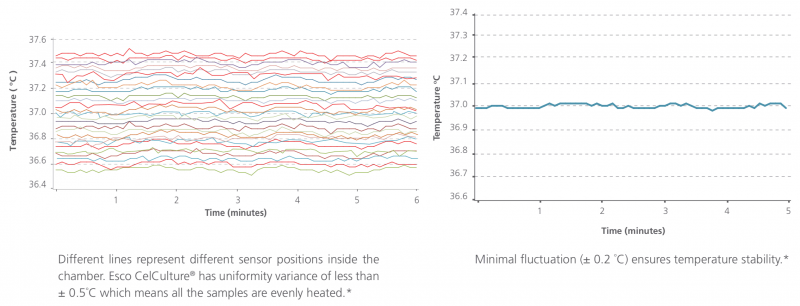

- Precise heating in the chamber is achieved by using 8 heaters located in 3 zones. The 3 zones are intelligently controlled by the microcontroller for best temperature uniformity and minimal fluctuation.

Company A’s model: overshoot. Company B’s model: slow recovery. Esco CelCulture®: fast recovery, no overshoot

Direct heating enables rapid temperature recovery while air jacket provides isolation against ambient temperature fluctuations. Precise heating in the chamber is achieved by using 8 heaters located in 3 zones. The 3 zones are intelligently controlled by the microcontroller for best temperature uniformity and minimal fluctuation.

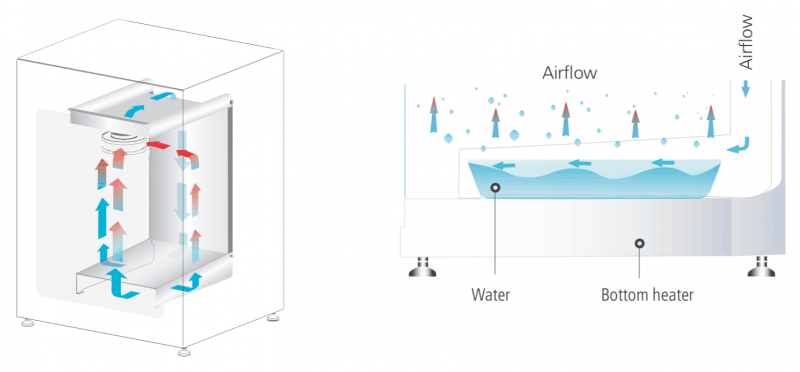

The main heater provides precise temperature control. The bottom heater warms the water pan and provides humidity. The outer door heater prevents condensation on glass door and facilitates temperature recovery.

- Blower automatically stops when door is opened to minimize mixing of chamber and room air.

- Accelerates recovery of chamber air to ISO Class 5 Cleanliness after door closing to prevent contamination.

- Improves CO2, humidity, and temperature uniformity.

- Filtered air circulates across water pan to accelerate humidifying process.

ROBUST CONTAMINATION CONTROL

- Chamber air is continuously filtered by ULPA filters to keep the chamber at ISO Class 5 cleanliness. This ensures that all contaminants from both room air and chamber air are filtered, thus only clean air is recirculated.

- ULPA filters operate at 99.999% efficiency, superior to conventional HEPA filters which are 99.99% efficient.

- Chamber achieves ISO Class 5 cleanliness 11 minutes after door closing.

- Proven 90˚C moist heat decontamination cycle deactivates resistant fungi, bacterial spores, and vegetative cells in less ta 15 minutes.

- Independently proven to be as effective as high temperature decontamination.

- Lower temperature causes less damage to electronic components prolonging the life span of the CO2 incubator.

Replaceable 0.2 micron filters remove impurities and contaminants before gases injection.

Ozone-free UV lamp decontaminates the water in the humidity pan and the circulating air. Cell culture safety is protected by isolating the UV lamp from the inner chamber.