Adherent Cell Culture Bioreactor

Esco is a worldwide a leader in the development of laboratory, pharmaceutical and bioprocessing equipment solutions. The Esco VacciXcell division focuses on the development and manufacturing of dedicated bioprocess innovative tools including their unique, scalable Tide Motion adherent cell culture bioreactor systems, bioprocess containment solutions for cell therapy and vaccine development, biopharmaceutical filling line systems, a benchtop CO2 incubator for cell culture, and more.

All technologies supported through their Biotechnology Center of Excellence to help end users develop the proper protocols for the optimal utilization of the equipment.

Products and Solutions

The CelXrocker is an ideal tool for 3D macroporous carriers process optimization in T Flasks. Its reduced size allows operation inside most CO2 incubators and/or refrigerators for an experiment controlled environment. Furthermore, this rocker is utilized to mimic Tide Motion principle of alternating (media and air) exposure of cells in macrocarrier as a precursor to a full tied motion system.

CelCradle is a single use bench-scale bioreactor system for high density adherent cell culture in large surface microcarriers. The unit fits inside a 6ft3 CO2 incubator (for batch culture) or 8.5ft3 CO2 incubator (for perfusion culture).

The bottles assembly comes double packed and pre-sterilized ready to use for your vaccine, stem cell, or viral production application. Tide Motion principle achieves very high cell densities. Its unique nutrition cycles maximize O2 transfer and reduced shear stress. Ideal to convert from roller bottle to single-use closed system.

One (1) CelCradle adherent cell culture bioreactor’s productivity equals 80 roller bottles or 16 spinner flasks. The single-use closed system is applicable to autologous and allogeneic cell therapies. System includes available Celfeeder for automatic perfusion control and accurate pH and DO control for inoculation.

This technology is established in a wide array of applications, including:

- Mammalian and insect cell culture

- Fermentation

- Monoclonal antibody production

- Gene and cell therapy (autologous & allogeneic)

- Viral vector production

- Pharmacokinetics study

- Vaccine production

- Drug discovery

- Protein production

- Proteome research

- Exosomes, etc.

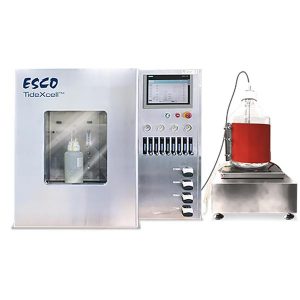

TideXcell® is a linearly scalable pilot bioreactor system that runs on Tide Motion principle. It is ideal for biomass expansion of adherent cells under single-use or multiple-use technologies. The pilot scale bioreactor includes pH and DO (Dissolved Oxygen) measurement capability, Siemens HMI or PLC-based monitoring and control system, compressed air path that comes with a double HEPA and VOC (volatile organic chemicals) filters as well as other accessories.

CelCradle X® is a single use, cGMP 21 CFR part 11 compliant closed automated bioreactor based on the Tide Motion platform. Ideal for autologous cell therapy applications by means of its automated harvesting system.

- Can be used as a standalone bioreactor or integrated with an Esco Laminar Airflow Cabinet, Biosafety Cabinet, or Cell Processing Isolator

- Automated seeding and control of pH/DO and glucose

The Esco CO₂ incubator for cell culture has unique features making it a highly reliable tool. Various options are available to match a wide array of applications, including:

- Filter installation

- Sterilization cycle

- UV lamp installation

- Chamber material

- External construction material, and

- Optional O₂ control

Systems supply CO2 (for pH) while maintaining the suitable temperature for cell growth. Additional features include: 90°C moist heat decontamination and 180°C high heat dry sterilization.