Tangential Flow Filtration System (Lab Scale)

Laboratory Tangential Flow Filtration System up to 0.5 m² and Single-Use TFF Systems up to 0.7 m²

High-performance automatic tangential flow filtration laboratory system for superior results. An excellent choice for research, development and small production purification.

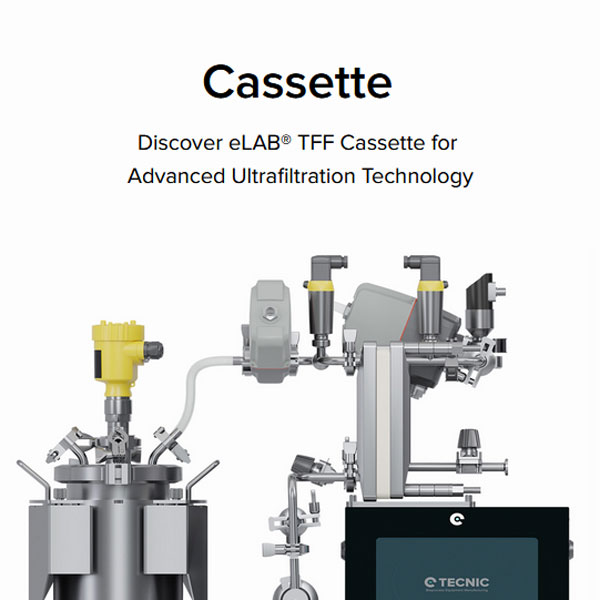

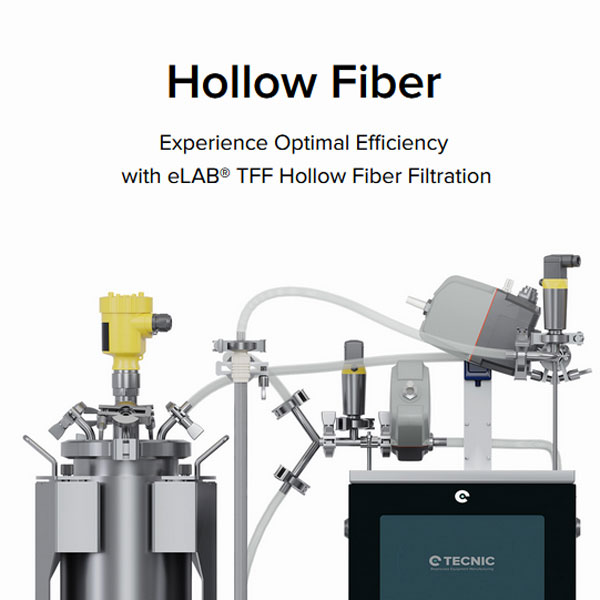

Engineered to meet the exacting standards of biotechnological downstream processes, TECNIC‘s eLAB® TFF fully automatic systems stand out for their exceptional filtration performance, reaching a maximum of 0.5 m² of total membrane surface area.

This achievement ensures unparalleled throughput and efficiency during continuous operations, facilitated by a meticulously designed tangential flow filter that minimizes membrane clogging and fouling. Notably, the system is particularly well-suited for concentration tasks involving proteins or antibodies.

Fully automated system achieving a max filtration surface area of 0.5 m². Highly flexible design compatible with Flat Sheet Cassettes, Hollow Fiber, or ceramic filters.

Normally supplied for most common TFF applications such as concentration and purification of biomolecules, this system is easily configurable to run other Microfiltration, Ultra-Filtration, and Nano filtration processes.

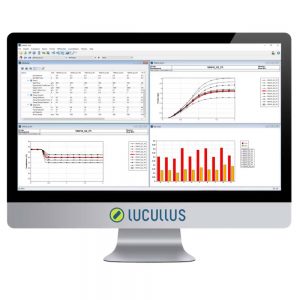

SS tank supplied in 5L or 10L standard capacities. eSCADA PLC-based software complemented by state-of-the-art sensors (pressure, flow, pH, UV, etc.) and automated valves for advance control of differential and transmembrane pressure and flow rates, along with other process parameters.

Ideal setup for high purity applications and contamination prevention. Single-use container volume ranges from 2 – 10 L and filtration area can reach up to 0.7 m².

Conical shape bottom single-use bag, manufactured in ISO7 clean room, minimizes product losses. Single-use components —including bag, filters, fluid path, and sensors—supplied preassembled as a gamma irradiated sterile kit assembly, and are easy to install or replace.

eSCADA PLC-based software complemented by state-of-the-art sensors (pressure, Flow, pH, UV, etc.), automated valves, and four piston diaphragm pumps for precise flow control and optimal recirculation, also provide advanced control of differential and transmembrane pressure and other process parameters.

TECNIC is a global manufacturer of high-quality, scalable bioprocess equipment for laboratory, pilot plant and GMP operations.

Their products/systems portfolio includes a comprehensive line of Bioreactors, TFF Systems, Mixing & Storage Equipment, and Buffer & Media Preparation skids in a wide range of sizes. This company focuses on innovation, providing standard state-of-the-art proven systems or customized solutions tailored to end users’ specific requirements. All products are available in reusable or single-use format. TECNIC’s supplies includes a large variety of single-use accessories designed for all their equipment including 2D and 3D bags, single-use bioreactor vessels and custom fluid path tubing/manifolds/filter kits. They also provide an extensive range of rigid plastic, borosilicate glass (jacketed and non-jacketed) and SS vessels and components.