Raman Spectroscopy Systems

Tornado Spectral Systems is a recognized leader in the field of fast and accurate process analysis. Their Raman analyzer products and accessories have been designed for process development, GMP manufacturing, and R&D laboratory applications.

Their complete product and solutions portfolio includes the:

- HyperFlux PRO Plus Laboratory Raman Analyzer: Monitor samples off-line or in-line and in real-time

- Process Guardian Inline Process Raman Analyzer

- SuperFlux Raman Analyzer: High Throughput Raman in a smaller package

- Hudson 785 high-performance Raman probe

- SpectroPort probe compatible with Sartorius Ambr® or Biostat STR® systems

- Highly secure and CFR11 compliant SpectralSoft software.

All products and solutions are created to perform at the highest standards of quality to meet the demanding requirements of industry and research.

Raman Spectroscopy Systems and Accessories by Tornado Spectral Systems

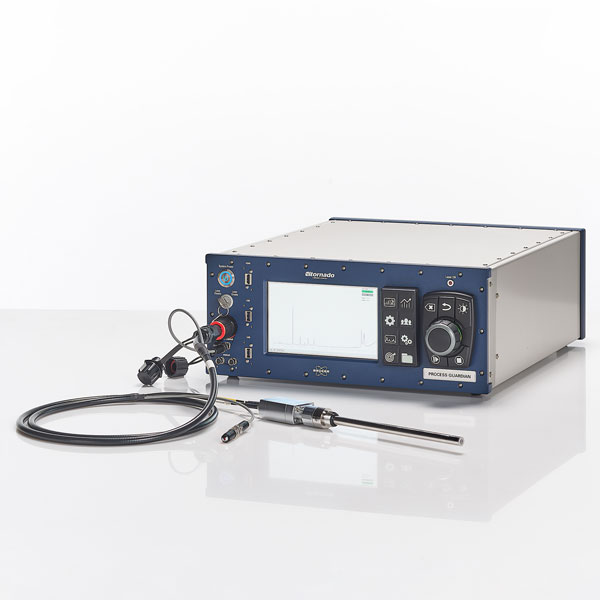

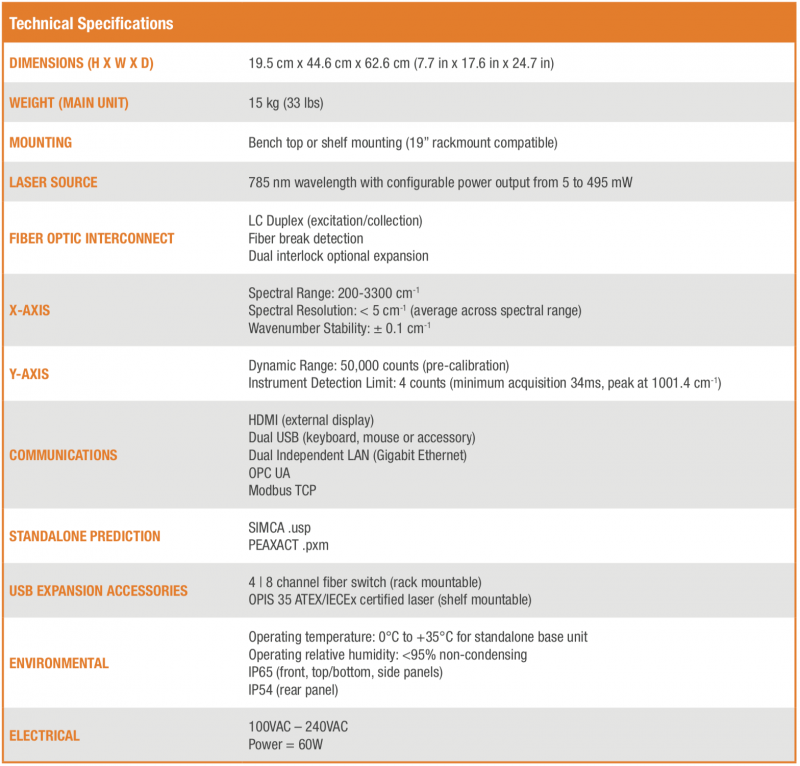

Process Guardian Raman Analyzer

Tornado Spectral Systems PROCESS GUARDIAN is a superior performance Raman analyzer specially developed for installation in demanding process environments. Its advanced design includes a next generation proprietary HTVS spectrometer coupled with a high quality stabilized laser, multiple laser safety interlocks, temperature monitoring, dynamic recalibration, and an automated diagnostics/fault detection system. HTVS eliminates slit loses while maintaining high spectral resolution, providing the best combination of signal strength, resolution and speed of response.

This Raman spectroscopy system has integrated HMI, allowing performance of full configuration tasks without the need of removing it to a safe area. Adding to the unique design, the LC duplex fiber cable connector, robust operator dial, and data acquisition capabilities make the PROCESS GUARDIAN the ideal analyzer for PAT GMP installations.

Features:

- In-line results in seconds

- Rugged design protects internal components against external environment

- Fully embedded instrument control and spectral processing platform

- User-friendly button and rotary dial control

- LAN connectivity and industry standard communication protocols

- Expandable to 4 or 8 channels with optional multiplexer accessory

- Supports OPIS 35 IECEx/ATEX certified laser accessory

- Wide range of probes for different applications including Non-Contact, Immersion (Sterilizable), Flowthrough for downstream operations, etc.

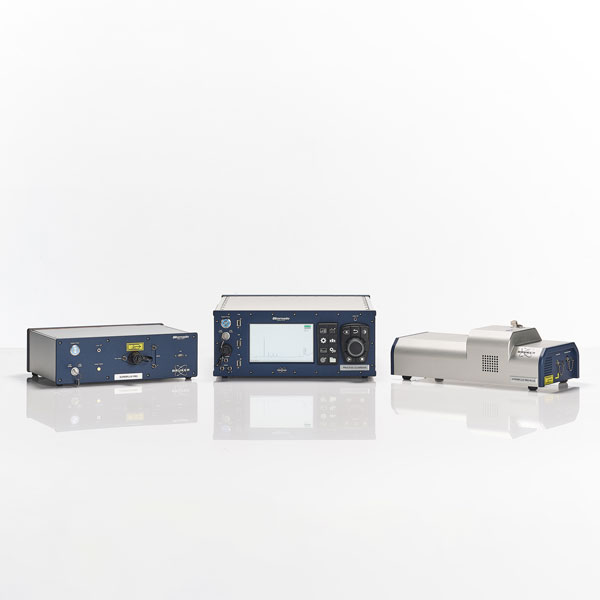

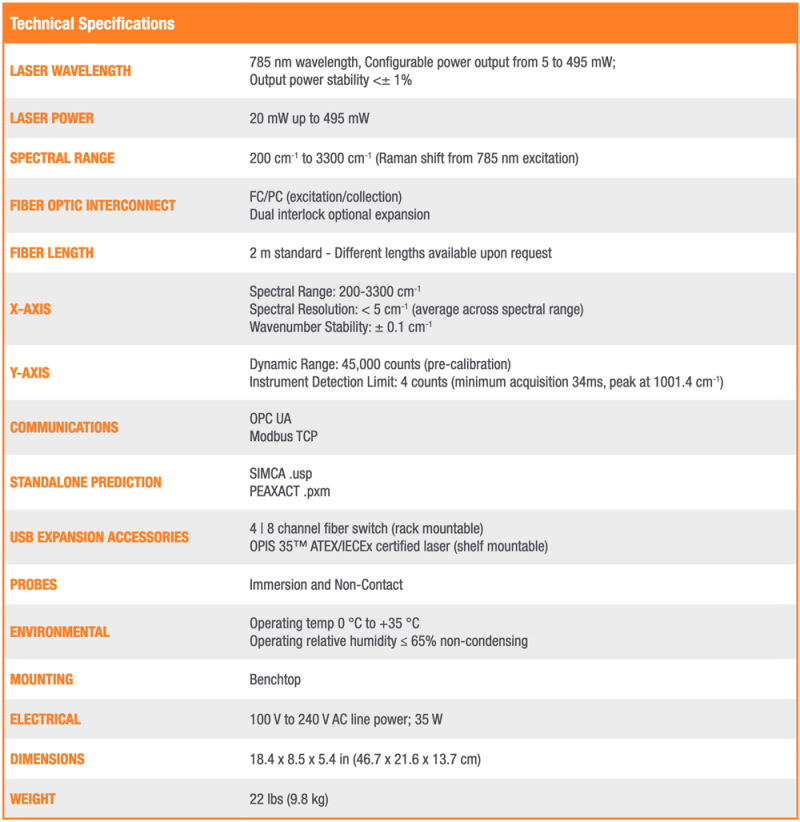

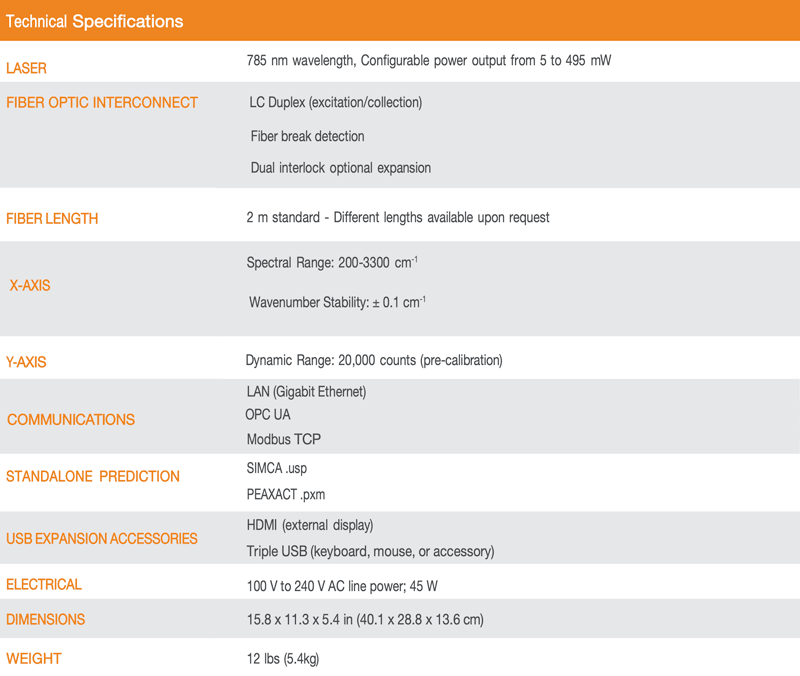

HyperFluxPRO Plus Raman Analyzer

- State of the art inline Raman Spectroscopy System that includes a proprietary HTVS-enabled spectrometer

- Includes an internal 785 nm laser light source with adjustable power between 5 and 495 mW

- Capable of providing faster measurements than alternative platforms in this space with better higher sensitivity at low detection limits

- Available probes for direct process immersion or non-contact measurement

- Compatible with a wide range of process probes, and chemometric software packages

SuperFlux Raman Analyzer – High Throughput Raman in a smaller package

Tornado’s SuperFlux (SFx) lab-scale analyzer is the ideal Raman Analyzer for lab-scale applications and for those who require lower spectral resolutions. The SFx is built on the same platform as our most robust and powerful analyzers, with HTVS technology, for which Tornado analyzers are known.

Features:

- Fit-for-purpose lab-scale Raman analyzer

- Built on the same revolutionary HTVS technology

- Compact desktop size of 12 lbs

- High sensitivity, low detection limits

- Embedded CPU – No external adapter needed

- Real-time non-destructive monitoring and analysis

- OPC UA client for remote control

- Easy installation and operation

High performance lightweight laser safety accessory for installation in Class 1 div 1 or div 2 areas (compliant with ATEX Zone 0). Allows high accuracy measurements at very low laser power settings.

- Stainless Steel – electropolished finish (R1 15) non-contact Raman probe developed for highly demanding laboratory and/or process applications.

- Physical design and rugged construction allows operation on highly dense and viscous bioprocess samples or other process applications.

- Rugged single core fiber optic cables allow longer transmission distances and utilization of multiplexers.

- Specialized sample optic selected for the specific use/process type.

- Compatible with external measurements through windows, sight glasses, and containers.

- Inline bioprocess measurement sampling devise especially compatible with Sartorius Ambr or Biostat STR systems.

- Full signal integration with Ambr Systems allows calibration models to be created and run directly on Ambr Control Computer.

- Completely sealed, monolithic single piece design with integrated optics provides highly stable measurement without misalignments or process ingress/contamination.

- Optimized to operate with Hyperflux’s HTVS technology

- High-performance process monitoring of bioprocess samples

- Optimized for compatibility with Tornado’s Raman spectrometers

- Robust and versatile for a wide range of biological processes

- Compact and lightweight

- Probe head optimized (etendue-matched) to the spectrometer, further boosting the throughput efficiency and measurement sensitivity

- High purity optical elements ensure low background

- No epoxy or gold seals, providing zero leaching risk

- Easy to use, highly powerful software which provides continuous monitoring results with raw data conversion into valuable process information.

- All setting parameters located in one single screen and bioprocess results available in real-time graphical spectrum display.

- Fully customizable, offering the following options:

- Multiple collection modules

- Automated calibration

- Integration with prediction engines

- Connectivity to wide array of Plat platforms

- Customizable HMI

- Control of up to 8 sample channels and full data integrity and operational security

Related article: Raman Spectroscopy in Bioprocessing: An Introduction to Spectroscopic Methods of Analysis & Applications in PAT

Please download our Raman Spectroscopy Technology Introduction for a quick introduction to the technology, common upstream and downstream applications in bioprocessing, and Tornado Spectral Systems’ high-throughput virtual slit technology principles and its advantages.