Reports

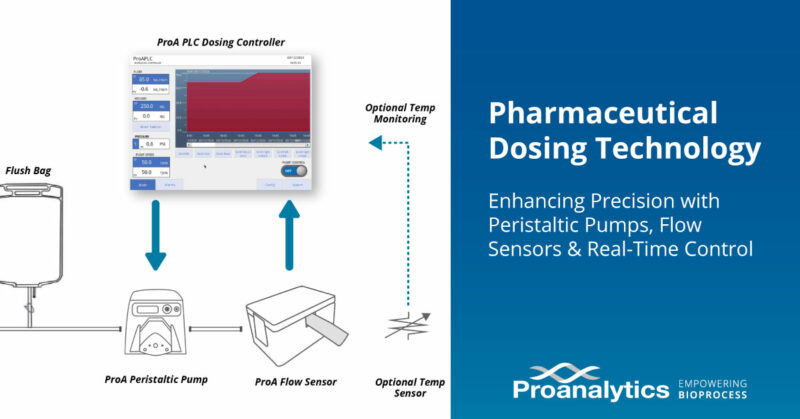

Pharmaceutical Dosing Technology: Enhancing Precision with Peristaltic Pumps, Flow Sensors, and Real-Time Control

Introduction

Dosing Systems and Dosing Technology for Pharma Applications

Accurate dosing is a critical task in the pharmaceutical industry, particularly in areas such as cell and gene therapy, stem cell research, and small-scale pharmaceutical production.

The integration of high-precision peristaltic pumps, ultrasonic flow sensors, and a real-time measurement and control system significantly enhances dosing accuracy and reliability. The ProA PLC bioprocess controller — equipped with real-time adaptive dosing control — provides a simple yet effective solution to automated dosing systems. It improves accuracy, reduces waste, and enhances product quality in precision filling applications.

Additionally, the ProA PLC control unit supports the integration of temperature and pressure sensors, further improving dosing accuracy and enabling broader application possibilities.

Dosing Technology Lineup

The Peristaltic Pump

Filling devices are extensively utilized across various industries for fluid handling, including both conveying and dispensing. In recent decades, peristaltic pump technology has become increasingly prominent in fluid transfer, filling, and dosing applications, particularly within the pharmaceutical industry.

In peristaltic pumps, the product comes into direct contact with only a single piece of tubing, which can be easily cleaned or replaced after use. This design feature makes peristaltic pumps an appealing choice for dispensing throughout bioprocess operations, as it greatly reduces the risk of cross-contamination. Additionally, adjusting the tube size allows for easy management of a wide range of filling volumes. The setup and calibration process can be completed in minutes, and new tubing material options have enhanced their ability to handle aggressive products.

The ProA Pump line of peristaltic pumps offers a variety of pump heads to accommodate different tubing sizes, dosing rates, and applications. Most are equipped with four rollers for enhanced accuracy, while dual pump head models are available for even greater precision and reduced pulsation.

The Ultrasonic Flow Sensor

The integration of real-time flow measurement into a fluid handling system enhances precision, consistency, and reliability. ProA Flow is a non-invasive sensor using ultrasonic technology which measures in real time and is not influenced by factors such as turbidity, charge, and temperature.

Accurate flow control is essential at every stage of bioprocessing, but particularly in dosing and finishing. Utilizing precise flow sensing offers valuable feedback to optimize any fluid handling process and enables the implementation of advanced feedback strategies for precision dosing and filling.

The Up/Downstream Bioprocess Controller

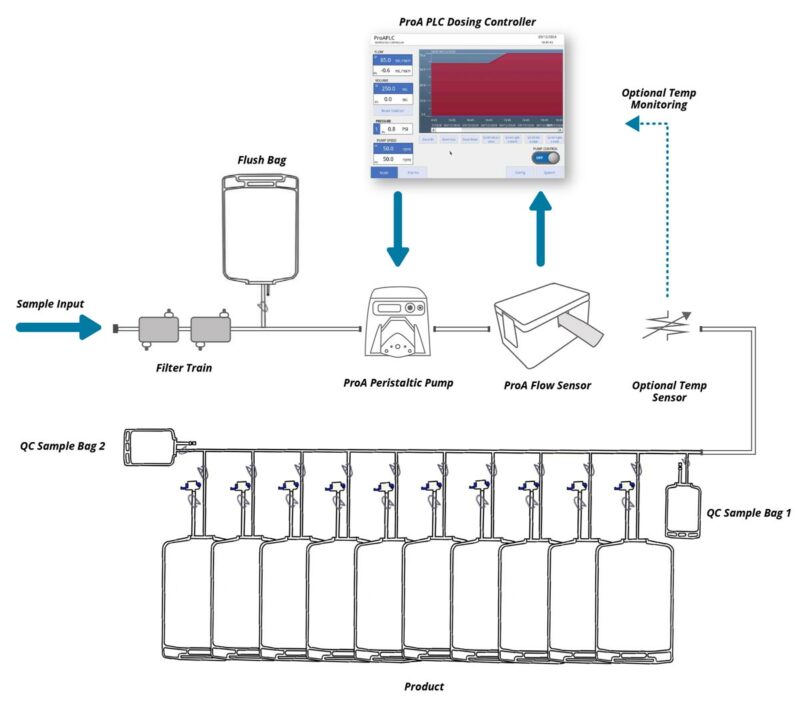

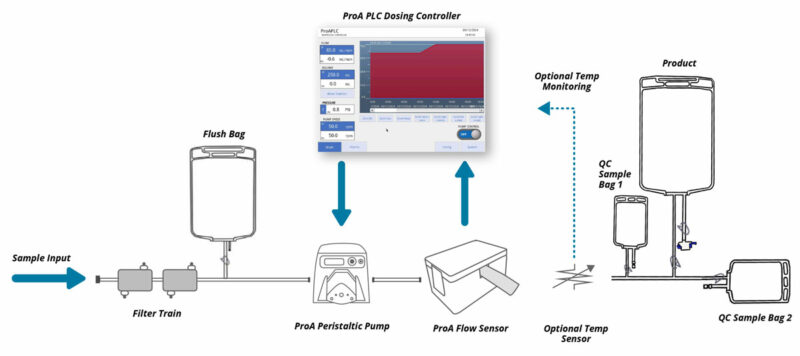

Integrating the pump and flow sensor into the ProA PLC Bioprocess Controller creates a high-precision filling and dosing device that comes with a wide range of features and can be highly customized. It includes pump and sensor calibration functions, display of key variables, alarms, and a selection of various process control strategies.

The ProA PLC leverages feedback and control strategies to optimize dosing accuracy and reliability. Real-time monitoring and control minimizes the impact of variables such as sample temperature, tubing temperature, and tubing wear. Custom control algorithms can be developed for specialized applications.

The system supports integration with other controllers or historian systems via Modbus or Ethernet connectivity. Additionally, ProA PLC can measure, display, and re-transmit data from other process sensors.

ProA PLC serves as the “brain” of the system, capable of connecting with a diverse array of pumps, flow sensors, and other process equipment. This flexibility facilitates integration with or expansion of existing processes, making use of pre-existing equipment.

Controlled Dosing System

The ProA PLC precision dosing unit incorporates intuitive controls for fast and easy configuration, set up, and start up of automated dosing. Installation of the dosing device takes only minutes and includes preconfigured control loops to suit most precision dosage and metering applications in the Pharmaceutical industry.

The simple user interface makes operation easy, with a fill set point and start button. Other parameters for process control are available, as needed, under a configuration tab. Custom interfaces can be provided offering users access to the tools they need to control the automated dosing process. Pump and sensor calibration is also available on the HMI.

Available with dual pump heads, suck-back angle settings, and temperature monitoring, the dosing system is designed for maximum efficiency and dosing accuracy. A custom dosing control program can be implemented to meet unique material handling challenges.

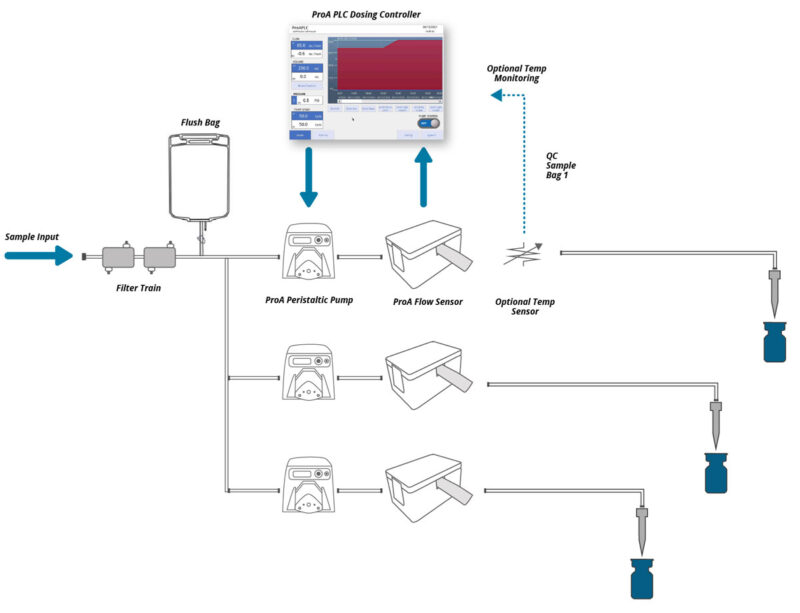

Parallel Dosing Technology

With a powerful PLC core, the dosing system can also be used to control multiple pumps, up to an 8 line vial filling system. Accurately control multiple fill lines and complete dosing in less time. Each line can be independently operated or used in a high-throughput filling/dosing process.

Summary of Features

- Provides high-precision dosing, even in complex applications

- 4, 6, 8 and 10 Roller pump heads ensure high precision and low pulsation

- Non-invasive clamp-on flow sensors increase dosing system accuracy

- HMI provides a local display of alarms, real-time values, graphs, and user controls

- Customizable for many fluid material handling projects

- Can be integrated with other process controllers, LIMS, pumps, or sensors

- Has been evaluated for use with bioprocess product streams, chemicals, and cleaning CIP materials

Flexible Dosing Technology

While this application note concentrates on precision filling and dosing systems for pharmaceutical use, the practical benefits of the system can extend to diverse industries such as food and beverages, as well as cosmetics. The dosing system capabilities are suitable for fluid and chemicals transfer and monitoring/management of various materials.