Pilot Scale Bioreactor

Pilot Scale Bioreactors from 10L to 50L and Accessory Equipment

The TECNIC pilot scale bioreactor series offers a unique solution in scalability and adaptability, allowing for the interchangeability of vessels between the cellular and microbial versions. Choose from CIP/SIP-compatible stainless steel or single-use vessels for your bioprocessing application.

Constructed in solid AISI 316L SS frames, the ePILOT scale bioreactor systems are supplied either as fully SIP/CIP units compatible with external steam or built-in steam generation, or in single-use vessel format for most common bioprocessing applications. Modular design allows exchanging SS vessels and adjusting to different working volumes, which adds flexibility and opportunity for scalability.

15-inch touchscreen interface provides advanced control via its SCADA and/or ADVANCED software. Fully programmable settings for recipe management, real-time data visualization, trend analysis and connectivity with external systems. Precise analytical measurements of pH, DO, temperature and antifoam level. Optional dCO2 and biomass measurements.

Fully configurable for mammalian or microbial cultures. A 400W Servomotor drive provides precise speed control, allowing for the most efficient mixing and optimal performance.

- Standard Sizes: 10, 20, 30 and 50 liter working volume

- Interchangeable vessels between cellular and microbial applications or different working volumes

- Key Components: External jacket, sparger, overlay gas inlets, rupture disc, addition valves, sensors ports, sampling kit, bottom valve and a front-integrated sight glass

- Jacketed vessels compatible with external steam or with integral AUTO SIP

- Wide selection of standard sizes including 30L, 50L, 100L, 300L and 1000L. Other sizes on request.

- Advanced eBAG 3D STR manufactured at TECNIC ISO7 Clean Room for highest sterility including full certification

- Mammalian configuration with pitch blade single-use impellers

- Microbial configuration with single-use Rushton impellers

- Standard ports for exhaust connection, overlay gas entrance, pH/pO2/Temperature sensors and liquid transfer or sampling

- Flexible bag design allows customization to fit specific process requirements

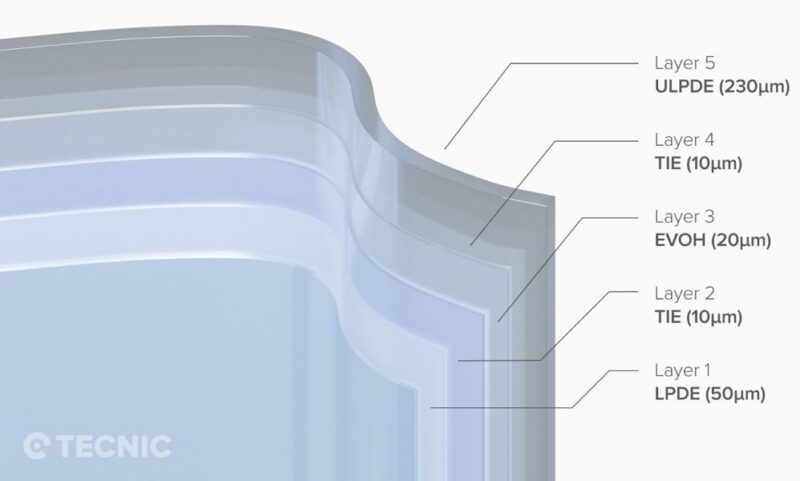

Five Layer Film structure serves a specific function to optimize product integrity, durability, longevity and sterility:

- Layer 1: (50 um) Low-Density Polyethylene (LDPE) provides mechanical strength and resistance to external factors

- Layer 2: (10 um) Thermoplastic Interlayer Elastomer (TIE) bonding layer for structural integrity preventing delamination

- Layer 3: (20 um) Ethylene Vinyl Alcohol (EOH) gas barrier

- Layer 4: (10 um) Second Thermoplastic Interlayer Elastomer (TIE) as bonding layer

- Layer 5: (230 um) Ultralow-Density Polyethylene (ULPDE) in direct contact with process liquids. Provides a Toxic-Free biocompatible environment.

TECNIC is a global manufacturer of high-quality, scalable bioprocess equipment for laboratory, pilot plant and GMP operations.

Their products/systems portfolio includes a comprehensive line of Bioreactors, TFF Systems, Mixing & Storage Equipment, and Buffer & Media Preparation skids in a wide range of sizes. This company focuses on innovation, providing standard state-of-the-art proven systems or customized solutions tailored to end users’ specific requirements. All products are available in reusable or single-use format. TECNIC’s supplies includes a large variety of single-use accessories designed for all their equipment including 2D and 3D bags, single-use bioreactor vessels and custom fluid path tubing/manifolds/filter kits. They also provide an extensive range of rigid plastic, borosilicate glass (jacketed and non-jacketed) and SS vessels and components.