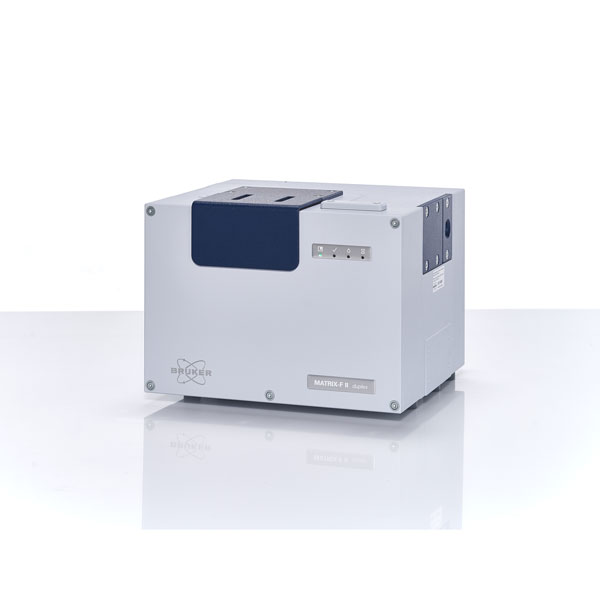

FT-NIR Spectrometer

Bruker‘s MATRIX-F II FT-NIR spectrometer is an in process-ready analyzer for reaction monitoring and control. This system provides direct inline measurements in pipes, reactors or other process equipment affording consistent high-quality results with the associated downtime reduction and increased productivity. The entire Bruker Spectrometer line is characterized by its robustness, long term stability and low maintenance requirements. There are thousands of Bruker Spectrometer installations in the Process Industries, including pharmaceutical production and food & beverage, substantiating Bruker’s reputation for quality and reliability.

Main Features:

- Accurate in-line results in seconds

- Multiple components per measurement

- Non-destructive analysis

- Optional built-in 6-port multiplexer

- Direct method transfer

- Rugged design

- 10 year warranty on moving parts of the interferometer and solid-state laser

- Ethernet connectivity and industry standard communication protocols

Bruker is a recognized worldwide manufacturer of high-performance scientific instruments and high-value analytical solutions for exploring life and materials at molecular, cellular, and microscopic levels.

In collaboration with end users and solutions providers like ProAnalytics, Bruker promotes innovation, improved productivity, and customer success in life science molecular research for pharmaceutical applications. Bruker’s PAT division offers a range of top quality products in Process and Laboratory Spectroscopy solutions, comprising Raman, FT-IR, FT-NIR, Mid IR, and NIR Analyzers.

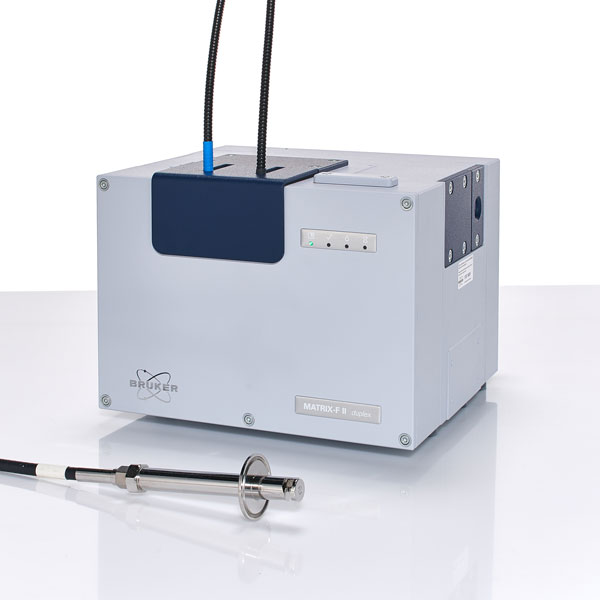

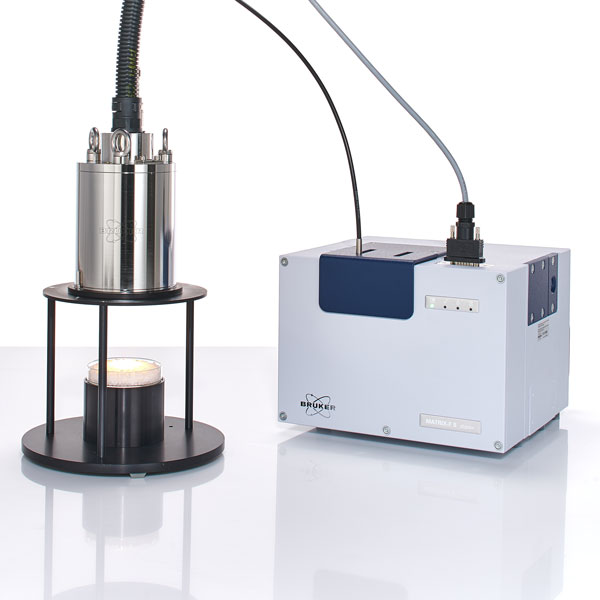

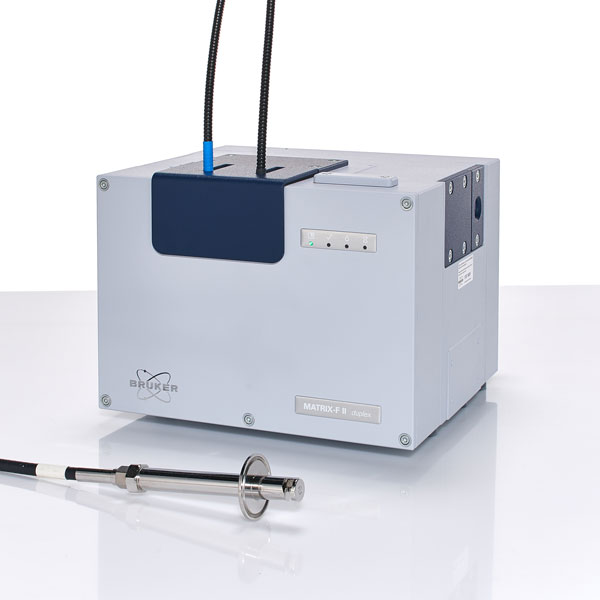

For inline applications, their extensive line of process interface devices includes Transmission Probes, Transflectance Probes, Reflectance Probes, and Flow Cells in a large array of process connections, materials of construction and sizes. This extensive line of equipment is utilized to analyze liquid, solid or gaseous samples in continuous or discrete mode. Its wide spectrum of applications includes incoming raw material ID, end products quality control, and process applications (chemical reactions, fermentation, filtration, chromatographic separation, mixing, blending, purification, drying, granulation, coating, etc.).