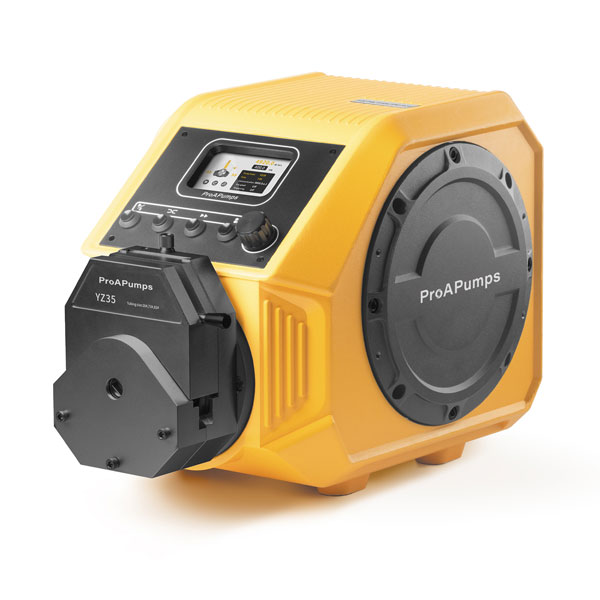

Explosion-Proof Peristaltic Pump (Yellow Pumps)

$10,442.40 – $13,468.80

Explosion-proof peristaltic pump

| Explosion Proof Peristaltic Pumps, IP66 Rating | ||||

|---|---|---|---|---|

| Name | RPM | Pump Head | Tubing | Flow Range (mL/min) |

| ExD-300 | 0.1-300 | DZ45 | #193, #88, #189, #191, #92 | 0.0019-28.15 |

| ExD-600 | 0.1-350 | DY35 | #26, #73, #82 | 1.28-13755 |

| DY25 | #15, #24, #35, #36 | 0.42-4340 | ||

| DY25-II (Dual Channel) | #15, #24, #35, #36 | 0.35-8278 | ||

| DY15 | #13, #14, #19, #16, #25, #17, #18 | 0.01-3337 | ||

| 0.1-600 | YZ35 | #26, #73, #82 | 0.7-12000 | |

| DZ25-6L | #15, #24, #35, #36 | 0.1-6000 | ||

| DZ25-3L | #15, #24, #35, #36 | 0.211-3600 | ||

- Tested IEC 60079 explosion proof standards

- 3 drive options: 150 rpm, 350 rpm, 600 rpm

- Flow rates to 28.15 L/min (7.4 GPM)

- Control range in 0.1 rpm increments

- Remote Analog/Digital, MODBUS control options

- Keypad uses optional security lock

- 5-year warranty against manufacturer’s defects

Safe & Reliable Liquid Transfer for Hazardous Environments

The chemical and pharmaceutical industry often handles toxic and volatile substances like organic solvents and acids. An explosion-proof peristaltic pump offers a safe and reliable solution for transferring these hazardous liquids.

The ProA ICPEx Series explosion-proof peristaltic pump is designed for use in explosive atmospheres, complying with stringent ATEX standards. These pumps are rigorously tested for electromagnetic compatibility (EMC) and grounded to prevent static electricity buildup.

These pumps are ideal for safely transferring a wide range of flammable liquids, including ethyl ether, ethanol, acetone, and benzene, across various industries such as pharmaceuticals, petrochemicals, and chemical processing.

Key Applications:

- Solvent Transfer: In chemical production, various solvents and solutions need to be transferred from one location to another. The explosion-proof peristaltic pump provides precise flow control and stable performance, ensuring safe solvent transfer for Methyl Chloride, Acetonitrile, Benzyl alcohol, ethanol, and more.

- Chemical Mixing: In some chemical reaction processes, different chemicals need to be mixed to facilitate the reaction. Explosion-proof pumps can deliver different chemicals to the reactor vessel in predetermined proportions to be mixed.

- Acid & Alkali Liquid Transfer: Many chemical/pharmaceutical processes require the transfer of acidic or alkaline liquids such as sulfuric acid, hydrochloric acid, sodium hydroxide, ammonium hydroxide, etc.

The selection knob and four rubberized buttons are waterproof, dustproof, and explosion-proof, ensuring durability in hazardous environments. Accurate fluid transfers are made easy with the onboard calibration screen.

The ProA ICPEx Series explosion-proof peristaltic pump is compatible with a variety of control systems for remote use and supports multiple fluid transfer options:

- Continuous: Fluid transfer mode at set flow rate, speed, and/or fixed volume

- Volume dispensing: Set volume, flow rate, number of repeats, pause time

- Flow Rate Dispensing: Set volume, flow rate, number of repeats, pause time

- Fixed Time and Volume Dispensing: Set volume, time, number of repeats, pause time

- Speed Dispensing: Set speed (rpm), time, repeat numbers, pause time

Read article: What Makes a Pump Explosion-Proof?

| Specifications | |

|---|---|

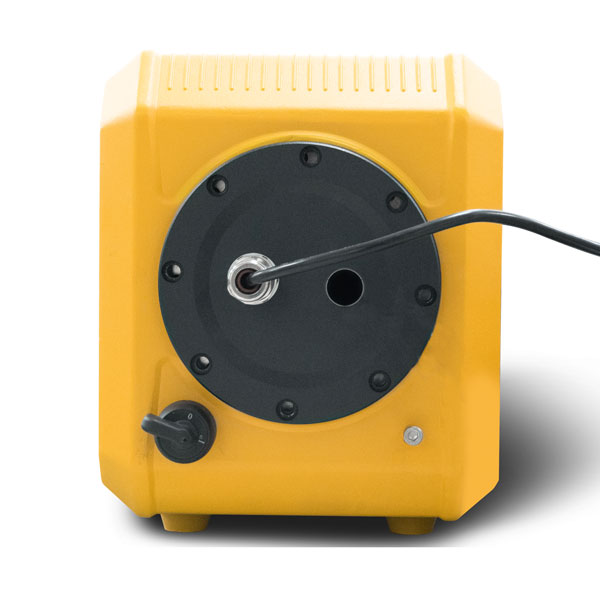

| IEC 60079 Marking | ɛx II2G Ex db IIC T4 Gb ɛx II2D Ex tb IIIC T1300C |

| Standards | EN IEC 60079-0:2018+A11:2024;EN IEC 60079-1:2014+A11:2024;EN IEC 60079-31:2018 |

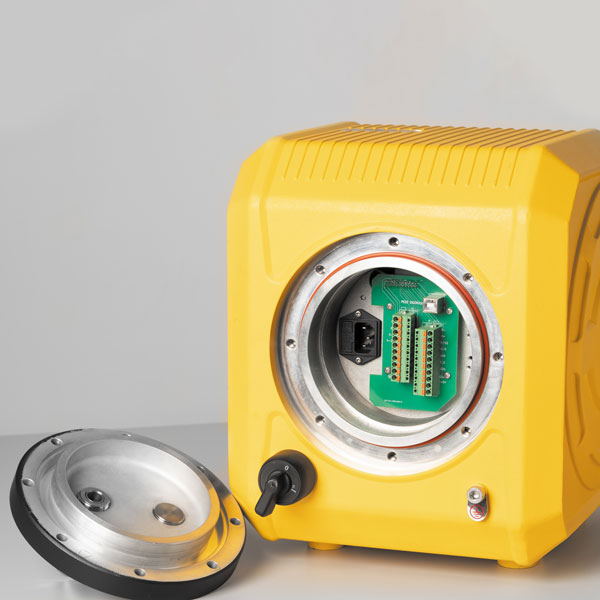

| Housing material | Aluminum Alloy |

| Speed range | 0.1- 350rpm |

| Speed resoution | 0.1rpm |

| Display | 4.3 inch-industrial grade- True color LCD screen |

| Control | Mechanical button, explosion proof knob, external control signal and communication |

| Working mode | Flow rate mode, Dispensing mode |

| Flow rate mode | Continuous transferring according to the set flow or motor speed |

| Dispensing mode | Set the dispensing volume, dispensing time, pause time and repeat numbers |

| Dispensing volume | 0.1ml- 9999L |

| Dispensing time | 0.1sec- 9999hour |

| Pause time | 0.5sec- 9999hour |

| Repeat number | 1-9999 times, o represent unlimited |

| Calibration function | Input actual volume and calibration automatically |

| Back suction angle | 0-3600 |

| Communication | RS485 |

| Communication protocol | Modbus protocol (RTU mode) |

| External control speed signal | 0-5v, )-10V, 4-20mA optional |

| External control signal input | Active Switch signal (5-24V) control start/stop, direction and full speed; passive switch signal control start/stop |

| External control signal output | Open collector output working status |

| Drive dimension (L x W X H) | 458 X 285 X 335mm |

| Power supply | AC220V±10%, 50Hz |

| Rated power | 300W |

| Relative humidity | <90% |

| Condition temperature | 0-400c |

| IP rate | IP66 |

| Drive weight | 30.1kg |