Reports

Preventing High-Density Cell Cultures from Fouling a Single-Use Continuous Centrifuge Using the ABER Optura SPY

Authors: Holly Sullivan, David Koechlein, Justin Lussier

Introduction

The ability produce biological drugs at lower costs and higher yields has been a major focus for biomanufacturing. With the advent of Single-Use Bioreactors and improved molecular biology, cell cultures can be > 20 x 106 cells/mL (1). Clarification of these cultures typically involves a primary depth filtration followed by a secondary round of filtration usually involving TFF before the product moves downstream (2,3). However, if clarifying large single-use bioreactors or fermentors, filters can be cost-prohibitive and cumbersome for the operator to handle. High cell-density cultures in intensified bioprocessing have made single-use clarification filter trains ineffective and impractical for handling large volumes (4).

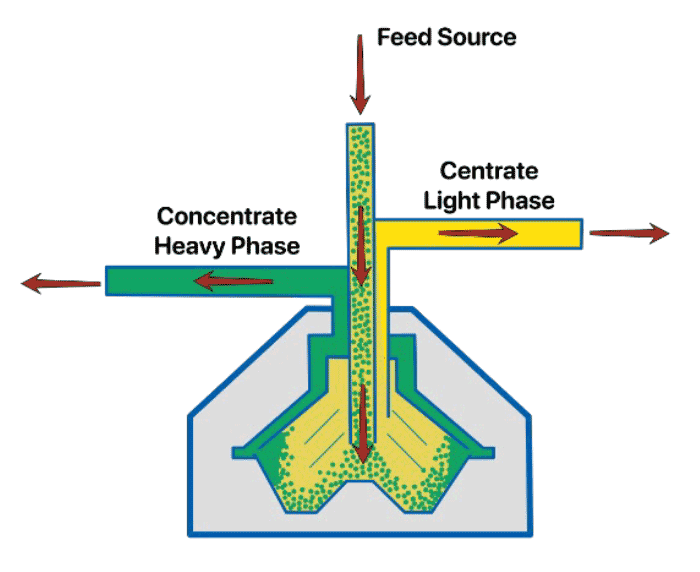

Using a single-use continuous discharge centrifuge to clarify high cell-density cell cultures from single-use vessels can significantly improve process times, increase yield, and lower the economics of the process (2). Single-use continuous discharge centrifuges use a combination of rotation and gravity to separate solids from the liquid. A feed suspension is pumped into the centrifuge where centrifugal forces push denser particles to the outside of the bowl and less dense liquids are pushed to the center. The design of the centrifuge bowl facilitates separation by using a series of conical plates, known as a disc stack, to move the clarified liquid to center and the solids to the periphery of the bowl where it is eventually discharged by the system (Figure 1). Turnaround time is also significantly improved since the centrifuge bowl and flow paths are single-use (3). A Single-use continuous discharge centrifuge has the following advantages:

- Depth filters require large amounts of flushing to remove leachables, extractables and particulates

- Larger batch sizes require larger filter surface areas – a significant increase in economics and facility footprint.

- Single-Use continuous discharge centrifuges have disposable centrifuge bowls & flow paths. They have a compact footprint which is an advantage for Contract Development and Manufacturing Organizations (CDMOs)

- SU Continuous Centrifuges can be integrated into Continuous Biomanufacturing processes easily

- Processing time is faster in a SU Continuous Centrifuge with higher product yield & greater reproducibility in comparison to traditional depth filtration techniques.

- Continuous Centrifuges have less cell shear forces and create less foam which makes clarification simpler and cleaner for downstream processing

- Single-Use Continuous Centrifuges have disposable centrifuge bowls and flows paths so there is no cross contamination of products.

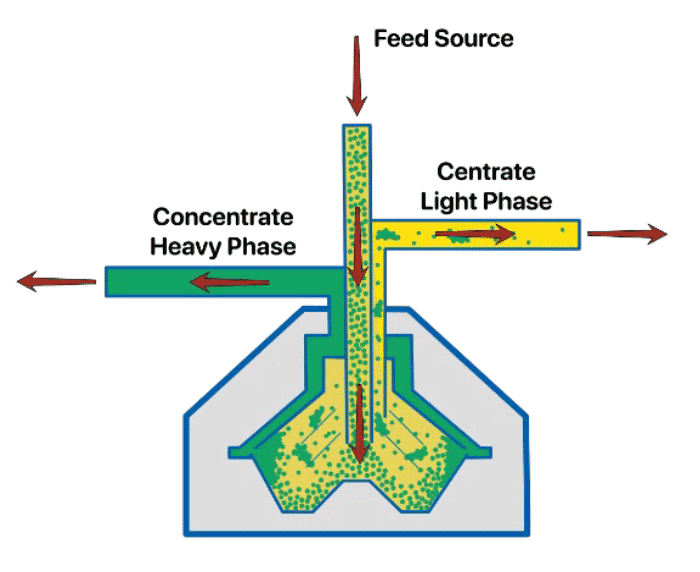

However, continuous centrifuges can also be fouled if the feed source or process stream becomes too dense or if large cell aggregates enter the centrifuge (Figure 2). In this application note, we will discuss a method for the real-time monitoring of any SU continuous discharge centrifuge using the ABER Optura SPY to provide feedback to the control system and prevent the centrifuge bowl from clogging.

Background

A single-use continuous discharge centrifuge clarifies reactors into two distinct phases from the feed source: the heavy phase (packed cells) and light phase (clarified supernatant) (4). The heavy phase accumulates at the periphery of the centrifuge’s bowl and is continuously discharged through the concentrate line, while the lighter clarified liquid is moved to the center of the bowl and discharged through the Centrate line (Figure 1). In continuous bioprocessing, monitoring the heavy and light phase is critical for ensuring optimal separation and maintaining the quality of the products.

Monitoring the turbidity of the system is important for detecting breakthrough, which occurs when a system becomes over-saturated due to cells and debris. This leads to clogging of the centrifuge bowl and contamination of the light phase (Centrate) by the heavy phase (Figure 2). Monitoring the turbidity in both heavy and light phases in real-time, operators can detect early signs of breakthrough and make necessary adjustments to the system to prevent the bowl from clogging.

Traditional methods of turbidity measurements depend on optical methods such as turbidimeters or nephelometry. Both measurements are based on detecting the intensity of light to determine concentration. Turbidimeters measure the absorbance of light which is proportional to the number of particles in solution. Nephelometers measure the amount of light scattered by particles in the solution (5). However, these methods have a limited range of measurement and can be over saturated if the feed source is too dense with cells and debris. Turbidimeters and nephelometers have the following disadvantages:

- Interference – Nephelometers and turbidimeters are susceptible to interference from other sources of scattered light, such as colored solutions, bubbles or contaminating stray light from other sources.

- Limited Range – Nephelometers and turbidimeters use light in the visible and near-infrared region (300 to 700 nm). Nephelometers are well suited for small particles at low concentrations. Turbidimeters are for more turbid solutions but are unable to detect small changes at high concentrations. Both methods depend on transmittance of light as it passes through the sample to the photodetector.

- Temperature Fluctuations – Nephelometers and Turbidimeters can be affected by temperature changes which can change the signal output leading to inaccurate turbidity measurements.

Centrifugation processes are developed by controlling the feed and concentrate flow rate. When harvesting, operators calculate the pack cell volume (PCV) of their feed sample. This is performed by spinning down samples and calculating the PCV for the feed & concentrate lines (4). PCV is expressed as a percentage of solids in the sample. These PCV values are entered into the control system of the centrifuge and system automation determines the optimal feed rate and discharge flow rate (the concentrate). The PCV value of the feed stream can vary throughout the harvest process and needs to be continuously monitored. If the PCV value inside the bowl (separation into heavy & light phases) is lower than the PCV value of the feed stream, the centrifuge discharges infrequently. If the PCV value inside the bowl is higher than the PCV value of the feed stream, the centrifuge discharges too frequently and clogs the system. The process needs to be balanced for effective separation into the heavy and light phases. Most single-use continuous discharge centrifuges use turbidity readings of the concentrate and Centrate lines to control the feed flow rate, rotational speed of the centrifuge bowl, and the control the valves needed for the backpressure of the centrifuge. Again, it is important to note that the feed stream can vary throughout the process. When the PCV values are greater than 85% solids in the feed stream, it is critical to monitor the system accurately or centrifuge discharge will clog and the Centrate will be contaminated with cells.

This application note discusses the use of the Optura SPY, a contactless biomass sensor, for monitoring both the heavy and light phase streams in a single-use continuous discharge centrifuge. The Optura SPY is different than typical spectroscopic techniques in that the SPY uses Bioreflectance instead of transmittance to determine concentration.

Overview of the Optura SPY

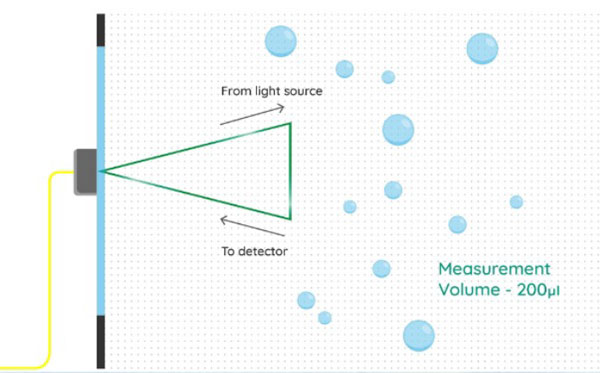

The Optura SPY uses a near-infrared beam to measure biomass concentration in culture vessels without direct contact. It adheres to the side of any vessel that is optically clear (Figure 3). It was developed to provide real-time, non-invasive biomass measurements of bacterial or cell cultures. The sensor is used to maintain the biomass for fed-batch processes or used to maintain a cell population for perfusion processes (feed and bleed operations).

The sensor emits a fixed length near-infrared (NIR) beam (1310 to1330 nm) and measures the amount of light that is reflected by the cells in the sample. This is called ‘bio-reflectance’. By measuring the optical properties of the biomass, the sensor can provide accurate and reliable data on biomass concentration in real-time. The sensor is not affected by bubbles that are found in the culture (Figure 4).

Turbidity Monitoring in Continuous Centrifuge Processes Using the Optura SPY

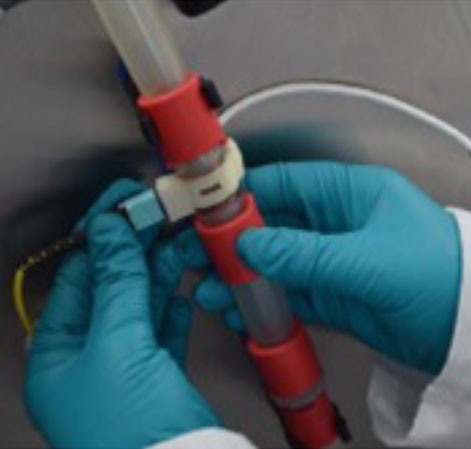

For this application, the Optura SPY is attached to the clear wall of a Pendotech pressure sensor. This area is optically clear, which allows the Optura SPY to transmit the near-infrared beam through the sensor housing. ABER Instruments has designed an SPY adapter that clips around the Pendotech pressure sensor (Photo 1). The adapter is used to monitor the heavy and light phase lines.

The SPY can be used with plastic or glass vessels and can transmit through various wall thicknesses.

Advantages of the Optura SPY in Continuous Centrifuge Applications

In a continuous centrifuge, the feed mixture is subjected to centrifugal forces that separate the sample into heavy and light phases based upon density. Breakthrough can occur at PCV >85% which can contaminate the product with cells. Integration of the Optura SPY allows for real-time detection of bowl breakthrough of the heavy phase into the light phase. Accurately monitoring of turbidity with the Optura SPY has the advantages of:

- Non-Intrusive Measurement: The Optura SPY is a non-intrusive PAT sensor. It eliminates the need for sample extraction or direct contact, reducing the risk of contamination and maintaining process integrity.

- Increased linear turbidity range: Other turbidity measurements use transmittance whereas the Optura SPY’s measurement employs bio-reflectance. Typical spectroscopic methods see a decreasing signal with increasing turbidity. The SPY uses bio-reflectance which gives a greater signal range in response to increasing turbidity and has a greater linear range of turbidity detection compared to traditional spectroscopic methods.

- Real-Time Monitoring: Provides continuous feedback on turbidity, enabling prompt adjustments to the centrifuge settings and to prevent the bowl from clogging. Monitoring the heavy phase will give the end user an early warning if the the source material is too dense which will clog the bowl and contaminate the light phase (centrate).

- High Accuracy and Sensitivity: Capable of detecting subtle changes in turbidity compared to traditional spectroscopic methods, leading to more precise process control.

- Process Optimization: Ensuring the correct separation of heavy and light phases ensures a clean product stream for further downstream processing.

- Quality Control: Maintaining consistent product quality by monitoring the turbidity and identification of breakthrough of the heavy phase into the light phase – indicating that the centrifuge bowl has clogged and contaminating the light phase.

- Efficiency Improvement: Reducing filtration waste, decreasing processing time, and improve the product yield by monitoring the separation process with the SPY.

Continuous monitoring of the heavy and light phase allows the operator to develop a “fingerprint” for the separation process, improving process reproducibility and consistency. Deviations from this fingerprint, such as breakthrough, allow the operator to stop the run or adjust parameters to save expensive runs from failure.

Offline Sampling and Generating a Calibration Curve

The Optura SPY has a default unit measurement in nanowatts which is a measure of the reflected light intensity (bio reflectance). The nanowatt readings can easily converted to any offline units of choice using offline sampling and generating a calibration curve. The calibration curve determines the offset which is a simple conversion factor between the two units.

Steps:

- Sensor Verification: The Optura SPY comes with a sensor verification block that is used before every run to confirm that the sensor is functioning properly.

- Calibration Samples: Throughout the process offline samples are taken from both the heavy and light phase streams. Offline samples are measured on turbidimeter. Data on the heavy and light phases are measured in real-time by the Optura SPY sensors and the results are logged on ABER’s OpturaView software.

- Calibration Curve Generation: Using the OpturaView software, calibration curves can be quickly generated from the offline samples. The OpturaView software aligns the offline sample values with the corresponding nanowatts reading and creates a calibration curve which can be used to evaluate future runs. Then real-time online data is viewed in units the operator has chosen (cells/mL, OD600, NTU, etc.).

Data Integration and Interpretation

The Optura SPY can integrate with process control systems through analog communication (4-20mA). Data from the sensor can be integrated into the process control system to enable real-time monitoring and automated adjustments.

Conclusion

The Optura SPY is a significant advancement in process analytical technology (PAT) for single-use continuous centrifuges. The Optura SPY sensor uses a non-contact near-infrared beam to interrogate the process flow. The SPY employs the principles of bio-reflectance which has greater signal range (near-infrared beam) than traditional turbidimeters that use light-based transmittance. The Optura SPY’s contactless, real-time measurement capabilities offer numerous benefits, including increased process optimization, enhanced process control to prevent clogging or fouling of the bowl, and improved product quality. The SPY’s contactless turbidity measurements enable the operator to actively monitor the SU continuous centrifuge to prevent fouling or breakthrough of the heavy phase (feed source >85%) into the light phase (clarified product).

References

- Agarwal H., Thwin C., Kumaar, B.T. Single-Use Centrifugal Separator Enables Intensification of the Clarification Process in Biomanufacturing of recombinant proteins. Journal of Chemical Technology and Biotechnology. Feb 2023

- Le Merdy, S. Evolving Clarification Strategies to Meet New Challenges. Bioprocess International.12(9) Oct 14 2014

- Richardson, A., Walker, J. A Solution to the Challenges of Clarifying High-Cell-Density Mammalian Cell Cultures. Broprocess International. 16(4) April 2018

- Hundley, R., Königsson, S. Development of a Single-Use Hermetic Centrifuge System for Mammalian Harvests with Moderate to High Cell Content. Bioprocess International. 18(10) Oct 2020

- Chianese, A. Bravi, M., Fazio, E. Turbidimetry and Nephelometry. Industrial Crystallization Process Monitoring and Control. Pp 51-57, 2012