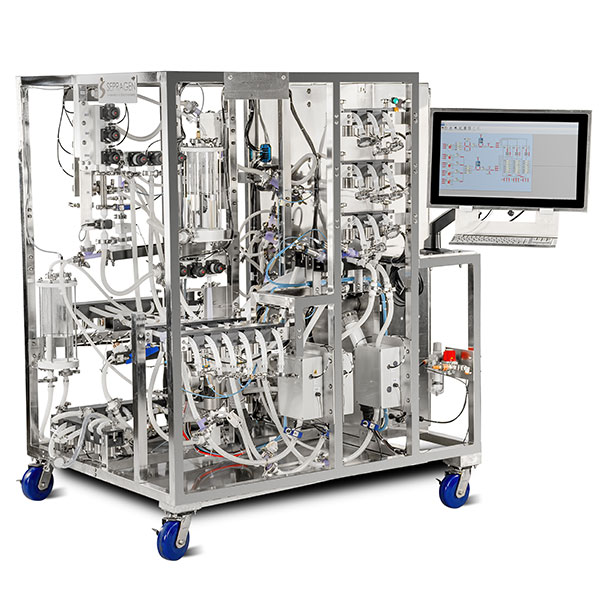

Chromatography System

Sepragen is dedicated to supplying powerful, innovative tools and technologies that enable our customers to develop and manufacture life-saving biological drugs, vaccines and diagnostics quickly and cost-effectively.

- Sepragen is a world leader in chromatography skids for over 35 years. There are more than 30 FDA approved drugs using a Sepragen chromatography system.

- Open architecture chromatography skids allow for traditional axial or fast flow radial chromatography columns.

- In-Line Buffer Dilution or Buffer Blending stand-alone skids or integrated into Chromatography system

- Automated, Dual-Sided, and Continuous Chromatography Systems available

- Increase your Process Intensification 4X!

- Small footprint instrument with ability to run up to 3 columns.

- Isocratic, Step, or Linear Gradients

- 12 CFR part 11 software compliant

- Wide flow range and Pressure Ranges

- In-line Dilution or In-line Buffer Blending Option

About QuantaSep® Trusty

The QuantaSep® Trusty is a versatile multi-use chromatography system. These systems can be run in automated or manual operations. Up to three axial or radial chromatography columns can be connected to the Trusty, which are all run in batch mode. Isocratic, linear, or step gradients are easy to program because the QuantaSep® software is user friendly – simple to learn and operate. The QuantaSep® Software is 21 CFR Part 11 compliant.

All Trusty systems are available to integrate with in-line buffer dilution (Trusty Premier systems) and in-line buffer blending ability (Trusty Elite Systems). These buffer dilution/buffer blending systems can save significant time in the creation and validation of buffers in a much smaller facilities footprint. Buffers are made at the point of operation from concentrated stocks.

All systems have dual 280 nm and 254 nm UV detection and dual pH, temperature, and conductivity sensors. Each system is equipped with two pumps (flow rate is model dependent), 8 or 12 buffer selection valves (model dependent) and 4 to 10 fraction collection valves (model dependent). Columns can be run in forward or reverse directions.

The Trusty systems come with active ultrasonic air traps and leak detection sensors to minimize product and buffer loss. The active air trap bypasses the need for a bubble trap and protects your chromatography column from air as well as avoiding any dilution or unexpected gradients caused by the holdup volume of traditional bubble traps. If air is detected in the line, it is automatically ejected from the system. The leak detectors ensure that there is minimal product and buffer loss if liquid is detected which automatically places the system on pause.

All Trusty systems allow for the automation of equilibration, loading, wash, elute, and regeneration of each column.

- Single-Use Flow Path means no cross contamination or cleaning!

- Small footprint instrument with ability to run dual columns

- Isocratic, Step or Linear Gradients

- 12 CFR part 11 software compliant

- Wide flow range and pressure ranges

- In-line dilution or in-line buffer blending option

About The Adept Single-Use Chromatography System

The Adept Single-Use Chromatography System is fully automated. The Adept can run axial or radial columns (Traditional and Single-Use Columns). QuantaSep® software is simple and intuitive when programming isocratic, linear, or step gradients, and is also 21 CFR Part 11 compliant.

These fully automated systems allow for the equilibration, load, wash, elute, and regenerate columns. All Adept systems are available to integrate with in-line buffer dilution (Adept Premier systems) and in-line buffer blending ability (Adept Elite Systems). These buffer dilution/buffer blending systems can save significant time in the creation and validation of buffers in a much smaller facilities footprint. Buffers are made at the point of operation from concentrated stocks.

All systems have dual 280 nm and 254 nm UV detection and dual pH, temperature, and conductivity sensors. Each system is equipped with two pumps (flow rate is model dependent), 8 or 12 buffer selection valves (model dependent) and 6 fraction collection valves. Columns can be run in forward or reverse directions.

Sterile single-use flow paths include all sensors for air, flow, pressure, conductivity, and pH. The Adept systems come with active ultrasonic air traps and leak detection sensors to minimize product and buffer loss. The active air trap bypasses the need for a bubble trap and protects your chromatography column from air as well as avoiding any dilution or unexpected gradients caused by the holdup volume of traditional bubble traps. If air is detected in the line, it is automatically ejected by the system. The leak detectors ensure that there is minimal product and buffer loss if liquid is detected which automatically places the system on pause.

- Continuous chromatography system

- Integrated in-line buffer dilution or in-line buffer blending

- Run up to 3 columns

- Isocratic, Step, or Linear Gradients

- 12 CFR part 11 software compliant

- Wide flow range and pressure ranges

About The Fusion Continuous Chromatography System

The Fusion Chromatography System is a family of large scale, single-use, continuous chromatography devices. Easy to learn QuantaSep® software is designed to be user-friendly, allowing you to program isocratic, linear or step gradients. Training takes only a few hours, is 21 CFR Part 11 compliant. These large-scale chromatography systems have integrated in-line buffer blending or in-line dilution from concentrated stocks. All buffers are made at the point of operation, which saves significant time in validation and QC of buffers as well as providing a far smaller facilities footprint.

Up to three axial chromatography columns can be connected to the Fusion, which can be run independently or sequentially with the previous column being washed and regenerated for the next run. All systems have dual 280 nm and 254 nm UV detection and dual pH, temperature, and conductivity sensors. Each system is equipped with two pumps (flow rate is model dependent), 2 to 6 buffer selection valves (model dependent) and 6 fraction collection valves. Columns can be run in forward or reverse directions.

Sterile single-use flow paths include all sensors for air, flow, pressure, conductivity, and pH. The Fusion systems come with active ultrasonic air traps and leak detection sensors to minimize product and buffer loss. The active ultrasonic air trap bypasses the need for a bubble trap and protects your chromatography column from air as well as avoiding any dilution or unexpected gradients caused by the holdup volume of traditional bubble traps. If air is detected in the line, it is automatically ejected by the system.

All Fusion systems allow for the automation of equilibration, loading, wash, elute, and regeneration of each column.

Like what you see, but doesn’t quite fit your process? We can build you a custom chromatography skid to fit your needs: redundant probes and sensors, extra inlets and outlets, or pumps configured to handle multiple flow rates. All standard models can be modified to meet your requirements as well. From R&D to cGMP, Sepragen and ProAnalytics has you covered!

ProAnalytics is a trusted partner of Sepragen, the original creators of Radial Flow Chromatography. For over 35 years, Sepragen has been providing Pilot and GMP scale chromatography purification equipment to the biopharmaceutical and Cell & Gene Therapy industries. All chromatography systems are open architecture allowing the user to switch between Sepragen’s fast flow radial columns and traditional axial chromatography columns from any vendor.

Larger Sepragen chromatography skids have in-line dilution and buffer blending capabilities. This results in a smaller operational footprint and the ability to make precise elution gradients at the point of use. Some systems allow for purification of multiple columns at different flow rates or experience the best in automation with Sepragen’s Continuous Chromatography skids with in-line dilution and buffer blending capacity. Increase your downstream Process Intensification with Sepragen, talk to a ProAnalytics Engineer today!